Impact Driver Screwdriver Bit Holders: Convenience And Efficiency

When it comes to maximizing the efficiency and longevity of your impact driver, the devil truly lies in the details or, more accurately, in the bits and their holders. Today, I will be zeroing in on a pivotal player in your toolkit: the Impact Driver Screwdriver Bit Holder. This seemingly modest accessory is anything but insignificant. It’s the linchpin that ensures your screws are driven home with precision, your work proceeds without a hitch, and your bits are managed with the utmost care.

In the following sections, I will dive deep into what makes a bit holder suitable for impact drivers, explore the various types available, and arm you with the knowledge to select the best Impact Driver Screwdriver Bit Holder for your toolkit. Let’s embark on this journey together, enhancing your tool mastery and ensuring your projects are not just completed, but completed with excellence.

The Purpose of a Bit Holder

The primary function of a bit holders to ensure that screwdriver bits are firmly attached to the impact driver, allowing for efficient transfer of the driver’s rotational and percussive power to the screw. It serves multiple key purposes:

- Security: It locks the bit in place, preventing it from falling out or wobbling during high-torque applications.

- Versatility: It allows for quick changes between different types and sizes of bits, enhancing the tool’s flexibility across various tasks.

- Protection: It contributes to the longevity of both the bits and the impact driver by absorbing some of the vibrations and impacts, reducing wear and tear.

Significance for Impact Drivers

The reason why a bit holder specifically designed for impact drivers is so crucial lies in the nature of the tasks these tools perform. Impact drivers are engineered for heavy-duty jobs that require not just spinning screws but driving them with a combination of rotational and hammering actions. This requires a bit holder that can:

- Withstand High Torque: The intense torque generated by impact drivers necessitates a bit holder capable of enduring without breaking or deforming.

- Absorb Shock: The pulsating action of an impact driver puts additional stress on the bit holder, requiring it to absorb shock and prevent damage to the bit and the driver’s internal mechanism.

- Maintain Bit Integrity: Frequent bit changes and the harsh conditions under which impact drivers operate demand a bit holder that ensures bits remain intact and effective over time.

In essence, the Impact Driver Screwdriver Bit Holder is not just an accessory; it’s a fundamental component that enhances the efficiency, versatility, and durability of your impact driver. Choosing a bit holder designed specifically for impact drivers is not merely a good practice, it’s a necessity for anyone serious about their tools and their work.

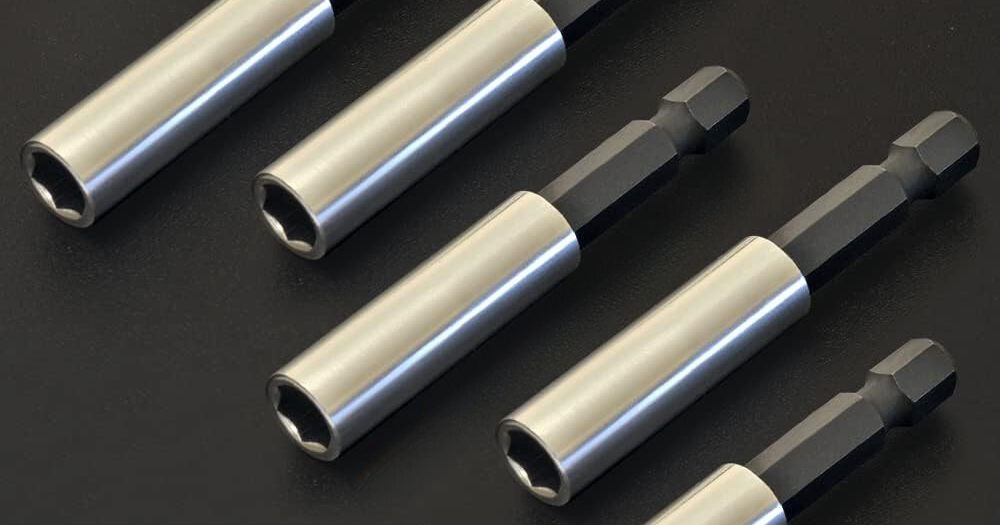

Types of Screwdriver Bit Holders for Impact Drivers

In the dynamic world of impact drivers, the choice of a screwdriver bit holder can make a significant difference in your tool’s performance and efficiency. Understanding the different types of bit holders available is essential for selecting the right one for your specific needs. Let’s explore the three primary types of bit holders designed for impact drivers: Magnetic Bit Holders, Locking Bit Holders, and Quick Change Bit Holders.

Magnetic Bit Holders

Description and Benefits:

Magnetic bit holders utilize a magnet to secure the screwdriver bit in place. This type not only ensures that the bit is held firmly but also helps in holding screws to the bit, making it easier to start driving screws into materials without having to hold them manually. The magnetic pull reduces the chance of dropping screws, which is particularly beneficial in tight or hard-to-reach spaces.

- Benefits:

- Easy to use, offering quick bit changes.

- Enhances precision by preventing screws from falling off.

- Ideal for working in confined spaces where manual screw placement is challenging.

Ideal Use Scenarios:

- Assembling furniture where precision and ease of use are crucial.

- Electrical installations, where holding tiny screws on the bit is beneficial.

- Any task requiring working overhead or in tight spots where dropping screws can be problematic.

Locking Bit Holders

Description and Benefits:

Locking bit holders feature a mechanical locking mechanism to secure the bit in place, often requiring a sleeve to be pulled forward or a collar to be twisted for the bit to be inserted or removed. This design ensures that the bit cannot come loose, even under the intense torque and vibration of impact driving.

- Benefits:

- Provides a secure hold, eliminating the risk of the bit falling out.

- Ideal for high-torque applications where bit slippage is a concern.

- Offers peace of mind when working on critical or safety-sensitive projects.

Ideal Use Scenarios:

- Construction projects that involve driving long or large-diameter screws where bit security is paramount.

- Heavy-duty applications where the tool is subjected to high levels of torque and impact.

- Projects requiring consistent bit retention for efficiency and safety.

Quick Change Bit Holders

Description and Benefits:

Quick change bit holders are designed for efficiency and speed, allowing for rapid bit changes with minimal effort. These holders typically feature a spring-loaded mechanism; by simply inserting the bit, it locks into place, and to release it, you push a sleeve or button. This design minimizes downtime and maximizes productivity on the job.

- Benefits:

- Fast and effortless bit changes, increasing work efficiency.

- Reduced interruption during tasks, allowing for a smoother workflow.

- Versatile and suitable for various projects, enhancing tool utility.

Ideal Use Scenarios:

- Projects with diverse screw types and sizes require frequent bit changes.

- Situations where speed is of the essence, such as in professional settings where time equals money.

- DIY projects or repairs where convenience and efficiency are valued.

Each type of screwdriver bit holder brings its own set of advantages to the table, tailored to different working conditions and project requirements. Whether you prioritize speed, security, or precision, there’s a bit holder designed to meet your needs, enhancing your impact driver’s performance and your overall productivity.

Watch This Video And Learn About Impact Driver Screwdriver Bit Holders: Convenience And Efficiency

Top Features to Look for in an Impact Driver Screwdriver Bit Holder

When it comes to enhancing your impact driving experience, not all screwdriver bit holders are created equal. The right features can significantly improve performance, ease of use, and longevity. Here are the top features to consider when selecting an impact driver screwdriver bit holder, ensuring you get the most out of your tool.

Magnetic Strength

The magnetic strength of a bit holder is a critical feature that can greatly influence your workflow. A strong magnetic hold ensures that your screwdriver bits and screws stay securely attached to the bit holder, reducing the risk of dropping screws and making it easier to work in tight or hard-to-reach areas.

- Why It Matters: Enhanced magnetic strength facilitates precision and efficiency, allowing for a smoother, more controlled impact driving experience. It’s especially beneficial when positioning screws before driving them, preventing frustrating losses and ensuring a tidy work area.

Locking Mechanism Quality

A high-quality locking mechanism in a bit holder is indispensable for heavy-duty impact driving tasks. This feature ensures that the bit remains securely fastened to the holder, even under the high torque and vibration tha impact drivers produce.

- Why It Matters: A robust locking mechanism prevents bit slippage during operation, ensuring consistent performance and reducing the likelihood of damage to the workpiece. It offers peace of mind, allowing you to focus on the task at hand without worrying about bit stability.

Resistance to Wear and Tear

Durability is a key factor in the lifespan of a bit holder. Resistance to wear and tear is essential, as the bit holder will be subjected to the intense forces of impact driving. Materials and construction quality play significant roles in how well a bit holder can withstand regular use.

- Why It Matters: A durable bit holder not only lasts longer but also maintains its performance level over time, offering better value for money. It ensures that the holder can withstand the high stresses of impact driving without degrading, providing reliable service through countless projects.

Ease of Bit Change

The ability to quickly and easily change bits can greatly affect the efficiency and flow of your work. Bit holders designed for easy bit changes can save time and frustration, especially when working on projects that require multiple types of screws or when dealing with damaged bits.

- Why It Matters: An easy bit change feature minimizes interruptions, allowing for a more streamlined and productive workflow. This is particularly valuable in professional settings where time is of the essence, as well as in complex DIY projects that demand flexibility.

When selecting an impact driver screwdriver bit holder, considering these features can lead you to a product that not only fits your specific needs but also enhances your overall work efficiency and satisfaction. Magnetic strength, locking mechanism quality, durability, and ease of bit change are all factors that contribute to a high-performing, reliable tool accessory, making your impact driving tasks more enjoyable and effective.

Best Practices for Use

Tips on Getting the Most Out of Your Bit Holder:

- Regularly Inspect for Wear and Damage: Before and after use, check your bit holder and bits for any signs of wear or damage. Replace any components that appear worn out to maintain optimal performance and safety.

- Use the Correct Bit for the Job: Match the screwdriver bit to the size and type of screw you’re working with. This not only ensures efficiency but also prevents damage to both the screw and the bit.

- Apply Even Pressure: When driving screws, apply steady and even pressure to prevent the bit from slipping out of the screw head, which can damage the screw, the bit, and potentially the work surface.

- Avoid Over-tightening: Be mindful of the torque setting on your impact driver to avoid over-tightening or stripping screws. This is especially important when working with softer materials.

- Clean Your Bit Holder Regularly: Keep your bit holder clean from dust, debris, and metal filings to ensure smooth operation. A clean bit holder also reduces the risk of rust and corrosion.

By following these simple steps best practices, you’ll ensure that your impact driver and screwdriver bit holder work together seamlessly, enhancing your tool’s functionality and making your projects more efficient and enjoyable.

Review of Popular Impact Driver Screwdriver Bit Holders

In the quest for the best impact driver screwdriver bit holder, several models stand out for their innovative features, durability, and user friendly designs. Here’s a look at some of the top contenders on the market, highlighting their key features, along with their pros and cons.

- Makita Impact Gold Ultra-Magnetic Torsion Insert Bit Holder

Pros:- Features a two-piece design engineered for maximum durability with less likelihood of bit breakage.

- Ultra-magnetic technology ensures a strong grip on bits and screws, reducing the risk of dropping them.

- Compatible with high-torque impact drivers, offering longevity even in heavy-duty tasks.

- Cons:

- The high magnetic strength might make it a bit difficult to remove bits after use.

- Pricier than some other options due to its premium build and features.

- DEWALT Magnetic Screw Lock Sleeve

Pros:- Magnetic Screw Lock system minimizes drops and reduces wobbles, enhancing precision.

- Compatible with a wide range of DEWALT impact drivers and screwdriving bits.

- Easy to use, making bit tip changes quick and hassle-free.

- Cons:

- The magnetic sleeve might not fit all screw sizes perfectly, limiting its versatility.

- Some users find the magnetic strength insufficient for very small screws.

- Bosch CC60482 2-Inch Magnetic Bit Tip Holder

Pros:- Made with high-quality materials, offering durability and a long lifespan.

- The compact size makes it easy to maneuver in tight spaces.

- Strong magnet provides a good hold on bits and screws.

- Cons:

- Lacks the torsion zone found in some other bit holders, which can lead to faster wear under high torque.

- Magnets might not be as strong as those found in some premium options.

- Milwaukee Shockwave Magnetic Bit Holder

Pros:- Designed for use with impact drivers, featuring a strong shock-absorbing zone for durability.

- The magnetic tip holds screws securely, allowing for one-handed operation.

- Engineered for extreme durability and up to 30X life.

- Cons:

- Some users report that the bit holder is too tight, making bit removal difficult.

- The length might be too short for users needing to reach into deeper recesses.

Each of these impact driver screwdriver bit holders brings something unique to the table, catering to different preferences and requirements. Whether you prioritize magnetic strength, locking security, quick-change convenience, or compact precision, there’s a bit holder designed to meet your specific needs and enhance your impact driving experience.

Wrapping Up The Impact Driver Screwdriver Bit Holders: Convenience And Efficiency

Selecting the right impact driver screwdriver bit holder is more than just an accessory choice; it’s a critical decision that impacts the efficiency, effectiveness, and enjoyment of your projects. Throughout this exploration, I’ve dive into the various types of bit holders, highlighted key features to look for, and reviewed some of the top models on the market. The journey through installation tips, best usage practices, troubleshooting common issues, and understanding the nuances of each type of bit holder underscores the importance of making an informed choice.

I invite you to share your experiences with impact driver screwdriver bit holders in the comments below. Whether you have a favorite model, a tip for maximizing efficiency, or a question about selecting the right bit holder, your insights can help create a community of informed and engaged tool users. Together, we can continue to learn, grow, and tackle even the most daunting projects with confidence.