Impact Driver Accessories And Attachments You Should Have

When it comes to power tools, an impact driver stands out for its sheer driving power and efficiency. But even the most robust tool can see its performance and versatility significantly enhanced with the right add-ons. That’s where impact driver accessories come into play. These accessories are not just additions; they are essential components that unlock the full potential of your impact driver, making every job more manageable, more precise, and faster to complete.

From drilling through tough materials to fastening screws with unparalleled precision, the right impact driver accessories ensure you’re not just doing the job but doing it well. This post I will dive deep into the world of impact driver accessories, exploring how these indispensable tools can transform the way you work, making every task more efficient and your impact driver even more powerful.

Understanding Impact Driver Accessories

The Basics of Impact Driver Accessories

Impact driver accessories are essential tools designed to enhance the functionality and versatility of your impact driver. They range from various bits and adapters to specific attachments meant for unique tasks, each serving a purpose to optimize your work. The primary goal of these accessories is to ensure that your impact driver can tackle a wide array of tasks with efficiency and precision. By choosing the right accessory, you can maximize the impact driver’s efficiency, allowing it to perform beyond just driving screws, including drilling, fastening, and even reaching into tight spaces where a standard drill might not fit.

Types of Impact Driver Accessories

The world of impact driver accessories is vast, with each type designed to meet specific needs. Here’s a look at some of the most common accessories:

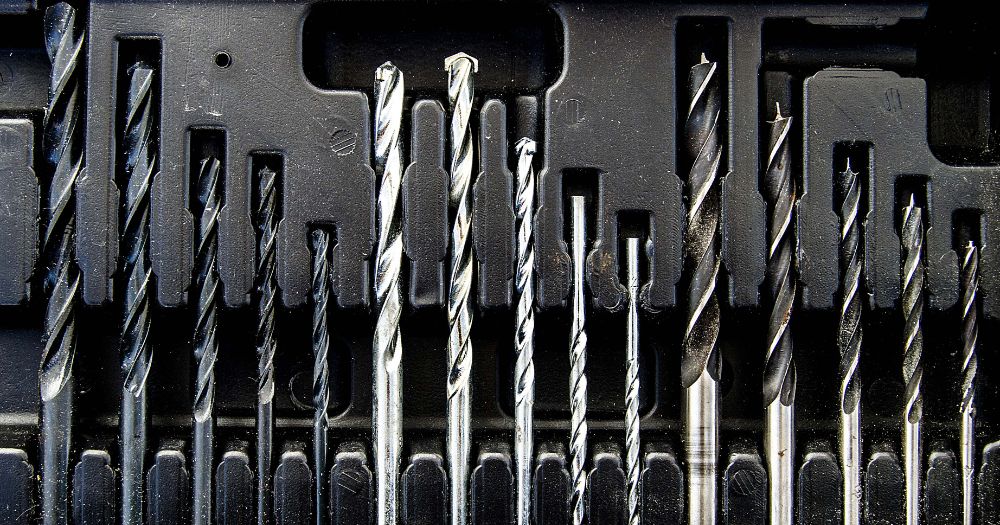

- Drill Bits: These are available in various sizes and materials to match the task at hand. For instance, high-speed steel (HSS) drill bits are perfect for drilling into metal, while carbide-tipped bits are ideal for tougher materials. The size and type of the drill bit you choose will depend on the material you’re working with and the size of the hole you need to make.

- Screwdriver Bits: There’s a wide variety of screwdriver bits available, each designed for different types of screws. From Phillips and flat-head to Torx and hex, selecting the right bit ensures that you can tackle any screw-driving task with ease, reducing the risk of damaging the screw head or the bit itself.

- Nut Drivers: Nut drivers are used for tightening and loosening nuts. They come in various sizes to fit the nuts you’re working with, making tasks like assembling furniture or working on mechanical projects simpler and faster.

- Socket Adapters: These accessories enhance the versatility of your impact driver by allowing it to use sockets, transforming it into a powerful nut and bolt driver. This is particularly useful in automotive work or any task involving the assembly of large machinery.

- Right Angle Adapters: For those hard-to-reach places, right-angle adapters are invaluable. They allow your impact driver to work in tight spaces where a normal drill configuration would be impractical, such as between joists or inside cabinets.

- Extension Bits: When you need to reach further than your impact driver allows, extension bits come into play. They can help you drill or drive screws in deep or awkward spaces, ensuring your work is not limited by the length of your bit.

Each of these accessories plays a crucial role in expanding the capabilities of your impact driver, making it a more versatile and indispensable tool in your arsenal. Whether you’re a professional contractor or a DIY enthusiast, understanding and utilizing the right impact driver accessories can significantly enhance your project’s efficiency and outcome.

Choosing the Right Impact Driver Accessories

Selecting the right accessories for your impact driver is crucial for maximizing efficiency, durability, and overall performance. Here’s how to make informed choices about the accessories you add to your toolkit.

Material Quality

The durability and performance of impact driver accessories are directly influenced by the quality of materials they’re made from. High-quality materials can withstand the high torque of impact drivers and provide a longer lifespan, even with heavy use.

- High-Speed Steel (HSS) is a popular material for drill and driver bits due to its toughness and resistance to high temperatures. It’s an excellent choice for general drilling tasks, especially in softer materials like wood and plastic.

- Carbide, on the other hand, is harder than HSS and maintains its sharpness longer, making it ideal for drilling into harder materials like metal and concrete. However, carbide can be more brittle and expensive.

Choosing the right material depends on the tasks you plan to tackle. For versatility and durability, investing in accessories made from high-quality materials is always recommended.

Compatibility with Your Impact Driver

Not all accessories fit all impact drivers, so ensuring compatibility is essential. The two key factors to consider are the shank size and type.

- Shank Size and Type: Most impact drivers use a ¼-inch hex shank, designed for easy and quick bit changes. However, the length and shape of the shank can vary, so it’s important to check that the accessories you purchase are compatible with your impact driver model.

Using accessories that properly fit your tool not only ensures optimal performance but also prevents damage to the accessory or the driver itself.

Task-Specific Accessories

Choosing accessories based on the specific job at hand can greatly enhance the efficiency and quality of your work.

- For woodworking projects, look for drill bits with brad points that prevent wandering and ensure clean holes. Screwdriver bits designed for wood screws can also help prevent stripping and splitting.

- In metalworking, opt for HSS or cobalt drill bits that can handle the hardness of metals. Nut drivers and socket adapters can be invaluable for assembling metal structures.

- For tasks involving concrete or masonry, carbide-tipped drill bits are essential for drilling holes for anchors or screws.

Selecting task-specific accessories not only improves the outcome of your project but also extends the life of your tools by ensuring they’re used in the conditions they were designed for.

Top Impact Driver Accessories Brands

When it comes to enhancing the functionality of your impact driver with accessories, choosing the right brand is as crucial as selecting the right tool. Some brands have established themselves as leaders in the industry, known for their quality, innovation, and reliability.

Leading Brands Overview

DeWalt is synonymous with durability and performance. Known for their tough and reliable tools, DeWalt’s impact driver accessories are no exception, designed to withstand the rigors of heavy-duty use while delivering precise results.

Milwaukee is celebrated for its innovation and heavy-duty performance. Milwaukee’s accessories, including their SHOCKWAVE series, are engineered for extreme durability and up to 30X life, making them a favorite among professionals.

Makita offers a wide range of high-quality accessories that complement their power tools perfectly. Known for their precision engineering, Makita accessories are designed for efficiency and longevity, ensuring your projects are completed to the highest standard.

Bosch is another top contender, with a reputation for high-quality engineering and innovation. Their accessories are designed for precision and durability, with a wide range of options available to suit various tasks and materials.

Brand-Specific Accessory Highlights

DeWalt Flex Torq Bits: DeWalt’s Flex Torq technology allows bits to flex up to 15 degrees, providing durability and reduced breakage for longer bit life. This makes them ideal for heavy-duty impact driving tasks.

Milwaukee SHOCKWAVE Impact Duty Driver Bits: Engineered for extreme durability and up to 30X life, these bits feature a unique Shockzone geometry to absorb peak torque and prevent breakage, making them perfect for demanding applications.

Makita Impact Gold Torsion Bits: Makita’s Impact Gold series is designed for high torque impact drivers, featuring high-strength torsion technology that extends the life of the bit significantly. The precision-fit tips reduce cam-out and stripping of screw heads.

Bosch Impact Tough Drill Bits: Bosch’s Impact Tough drill bits are designed to withstand the high torque of today’s impact drivers. With an upgraded design that includes a longer life and faster drilling speeds, these bits are ideal for tough materials.

Each of these brands brings something unique to the table, whether it’s durability, innovation, or precision. When choosing accessories for your impact driver, considering products from these reputable brands can ensure you’re getting the best performance and value for your investment.

Watch This Video And Learn About Impact Driver Accessories And Attachments You Should Have

Innovative Impact Driver Accessories

In the realm of power tools, innovation never ceases, and impact driver accessories are no exception.

Latest Advances in Accessories

The latest innovations in impact driver accessories have brought about a range of features designed to tackle challenges faced by professionals and DIY enthusiasts alike. These include:

- Flexibility and Reach: New flexible extension bits allow users to navigate around obstacles, reaching screws and fasteners that were previously inaccessible. This flexibility significantly enhances the versatility of the impact driver.

- Precision: Advanced bit designs feature precision-engineered tips that greatly reduce the risk of cam-out, ensuring that screws are driven cleanly and efficiently every time. This precision is particularly valuable in delicate or precision-critical tasks.

- Durability: With the introduction of impact-rated bits made from proprietary steel blends and featuring specialized heat treatment processes, these accessories can withstand the high torque of impact drivers much better than their predecessors, extending their usable life.

- Universal Compatibility: Recent developments include multi-size sockets and adapters that fit a wider range of bolt and nut sizes. This universal compatibility means users need fewer accessories to complete a job, simplifying their toolkit and the work process.

These advancements not only make tasks quicker and easier but also open up new possibilities for what can be achieved with an impact driver, pushing the boundaries of efficiency and versatility in power tool usage.

Accessories for Enhanced Safety

While performance is critical, safety remains a paramount concern. The latest wave of impact driver accessories includes features specifically designed to enhance user safety, such as:

- Anti-Drop Systems: Some bits and sockets now come with features that prevent them from accidentally dropping out of the driver, reducing the risk of injuries on the worksite.

- Shock-Absorbing Designs: Accessories equipped with shock-absorbing zones minimize vibrations transferred to the user, reducing fatigue and the risk of vibration-related injuries over long periods of use.

- Enhanced Visibility: High-visibility markings and even LED-equipped accessories improve accuracy in low-light conditions, reducing the risk of mishaps and ensuring precise work.

- Safety Gear: Beyond the accessories for the drivers themselves, advancements in safety gear specifically designed for impact driver use, such as gloves with improved grip and protection, goggles that offer clearer visibility and impact resistance, and ear protection that dampens the sound without isolating users from their environment, are equally important.

These safety focused innovations are crucial, as they not only protect the user but also enhance the overall efficiency and quality of the work by allowing for longer, more comfortable, and focused sessions.

Wrapping Up Impact Driver Accessories And Attachments You Should Have

Throughout this exploration of impact driver accessories, I’ve uncovered the vast potential these tools hold for enhancing the versatility and efficiency of your impact driver. From drilling and fastening to navigating tight spaces and tackling specialized projects, the right accessories can transform your impact driver into an indispensable powerhouse in your toolkit.

Drop a comment below with your stories, tips, and questions about impact driver accessories. Your insights not only enrich our community’s knowledge but also help others navigate their options more effectively. Let’s learn from each other and continue to push the boundaries of what we can achieve with our tools.

More Resources: