How to Use a Bench Grinder Safely: A Beginner’s Guide in 3 Easy Steps

Hey there, my fellow tool enthusiasts! Today, I’m thrilled to tackle a subject that’s near and dear to my heart – safety. And I’m not just talking about any safety; I’m zeroing in on how to use a bench grinder safely.

You see, a bench grinder is more than just a tool; it’s an indispensable ally in my workshop. But like any powerful ally, it demands respect and caution. From flying sparks to rapidly rotating parts, this machine can pose potential hazards if not handled with the care it deserves.

In this comprehensive guide, I’ll personally walk you through the essential steps to ensure your safety while using a bench grinder. I’ll cover everything from the necessary safety gear that I never work without, to the correct operation procedures I follow, and even the common mistakes I’ve learned to avoid over the years. Whether you’re a seasoned pro like me or a beginner just setting foot on your journey in the world of tools, this guide is tailor-made for you. So, grab your safety glasses, and let’s embark on our path to safer, more efficient bench grinder use!

Suggested Reading: How To Sharpen A Wood Lathe: A Beginner’s Guide in 9 Steps

What is a Bench Grinder?

Hello again, my fellow tool enthusiasts! Let’s take a moment to get to know one of my workshop’s MVPs – the bench grinder.

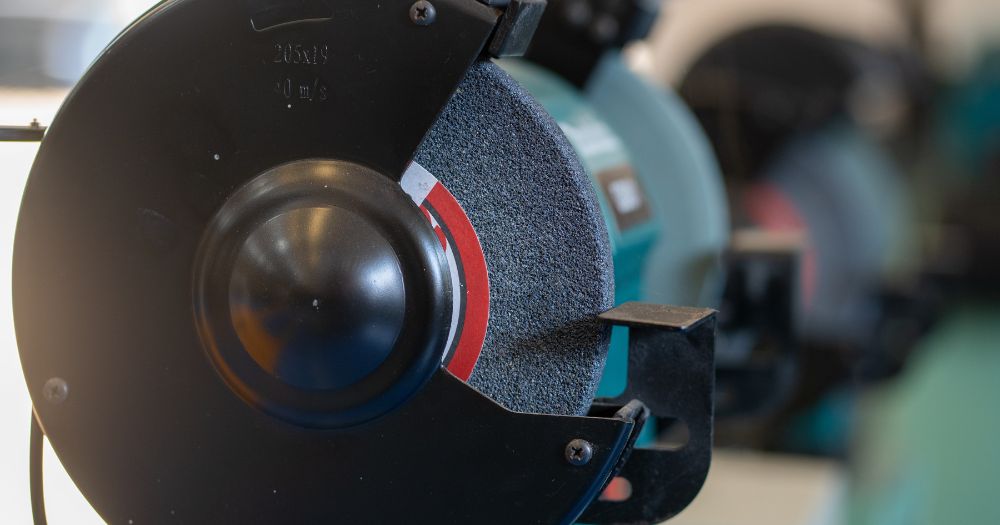

A bench grinder is a type of power tool that I always secure to a workbench or a sturdy table for stability. It’s equipped with two grinding wheels, one on each end of the motor shaft. These wheels come in different grits, making the bench grinder a versatile tool that I turn to for a variety of tasks.

So, what tasks am I talking about? Well, my bench grinder is my go-to tool for grinding, sharpening, buffing, and polishing various materials. Whether I need to sharpen my chisels, buff out some rough edges, or grind down a piece of metal, my bench grinder is always ready for action.

Bench grinders come in different sizes and power ratings to suit different tasks and workloads. The size usually refers to the size of the grinding wheel, not the grinder itself. Each wheel can be a different grit size, which means I can use one wheel for coarse grinding and the other for fine grinding.

In a nutshell, a bench grinder is a powerful, versatile tool that, when used correctly and safely, can be a game-changer in any workshop. Now, let’s roll up our sleeves and delve into how to use it safely. Stay tuned!

Essential Safety Gear for Using a Bench Grinder

As a tool enthusiast and someone who prioritizes safety above all else, I cannot stress enough how crucial it is to have the right safety gear when using a bench grinder. Ensuring my safety is not just a best practice; it’s an absolute necessity. Before I even think about powering up my bench grinder, I always make sure to have the following essential safety gear in place:

Safety Glasses

Let’s start with safety glasses – they are an absolute must-have when it comes to using a bench grinder. The grinding process can produce small particles and debris that can easily fly into my eyes, causing serious injuries. I never take any chances with my eyesight, so I always wear my safety glasses whenever I’m operating the bench grinder. I make sure to choose glasses that fit snugly and provide adequate coverage, giving me peace of mind while I work.

Work Gloves

Next on my safety checklist is a trusty pair of high-quality work gloves. Bench grinders can generate sparks and throw off hot metal shards, which can be harmful to my hands. To protect myself, I always opt for sturdy work gloves that offer both protection and dexterity. These gloves allow me to handle the workpiece with precision while keeping my hands safe from any potential hazards.

Dust Masks

Grinding can also produce a significant amount of dust, especially when working with certain materials. Inhaling this dust can be harmful to my respiratory system. To safeguard my lungs, I always wear a dust mask or a respirator when using the bench grinder. This precaution is especially important when dealing with metals or materials that may produce harmful dust particles.

Hearing Protection

Bench grinders can be quite noisy, and prolonged exposure to the noise can lead to hearing damage. To protect my hearing, I always wear earplugs or earmuffs while operating the grinder. These simple yet effective pieces of hearing protection ensure that I can focus on my work without putting my long-term hearing health at risk.

Having the right safety gear not only reduces the risk of accidents and injuries but also allows me to work with confidence and peace of mind. Before I start grinding, I always take a moment to double-check that I have all my safety gear in place. It’s a small step that makes a significant difference in ensuring a safe and productive work environment.

Remember, safety is not negotiable, and investing in the proper safety gear is an investment in my well-being. So, I always gear up and prioritize safety when using a bench grinder or any other power tool in my workshop. After all, my safety is in my hands!

Pre-Use Safety Checks

As a safety-conscious tool enthusiast, I know that taking a few moments for pre-use safety checks can make all the difference in ensuring a smooth and accident-free bench grinder operation. Before I start working, I always go through these essential pre-use safety checks to guarantee that both my grinder and work area are in top-notch condition:

Inspecting the Grinder

The first order of business is to carefully inspect my bench grinder. I pay close attention to the grinding wheels, checking for any signs of wear, cracks, or chips. A damaged wheel can lead to disastrous consequences, so if I spot any issues, I replace the wheel immediately. I also ensure that the wheels are securely mounted on the grinder, as any wobbling or imbalance during operation can lead to unwanted accidents.

Additionally, I confirm that the safety guards are intact and properly installed. These guards act as a protective shield, preventing sparks and debris from flying towards me while I’m working. Trust me; it’s a small investment in safety that pays off significantly.

Checking the Work Area

Next, I turn my attention to the work area surrounding the bench grinder. A clean and organized workspace is not just a matter of aesthetics; it plays a crucial role in ensuring my safety. I remove any clutter or debris from the area to prevent any tripping hazards. A clear and clutter-free space also allows me to move around comfortably and maintain better control over the workpiece.

Moreover, I make sure that the work area is well-lit. Proper lighting is essential for a clear view of the workpiece and the grinding wheels. This visibility enables me to make precise adjustments and ensures that I’m grinding with accuracy and confidence.

Preparing the Grinder for Use

With the grinder and work area thoroughly inspected and organized, it’s time to prepare the grinder for action. I adjust the tool rests, ensuring that they are close to the grinding wheels but not touching them. Properly positioned tool rests are vital as they allow me to maintain control over the workpiece and guide it smoothly across the grinding wheels.

Additionally, I check the spark guards and confirm that they are correctly positioned. These guards play a significant role in shielding me from any sparks or debris that might be generated during the grinding process. By keeping my work area protected, they provide an extra layer of safety during operation.

By investing a few minutes in these pre-use safety checks, I create a safer work environment for myself. These simple yet crucial steps give me the confidence to operate my bench grinder with peace of mind. After all, when it comes to safety, there are no shortcuts. Now, with my safety gear on and my grinder fully prepared, I’m all set to tackle my tasks with precision and caution. Let the grinding begin!

Watch This Video And Learn About How to Use a Bench Grinder Safely

Suggested Reading: Top 10 Carbide Lathe Wood Turning Tools for 2023

Safe Operation of a Bench Grinder

Now that I’ve covered the essential safety gear and pre-use safety checks, it’s time to dive into the safe operation of my bench grinder. Using this powerful tool requires knowledge, skill, and above all, a commitment to safety. Let’s walk through the step-by-step process of safely operating a bench grinder:

1. Starting the Grinder

Before I start my grinder, I ensure that I have all my safety gear on – safety glasses, work gloves, dust mask, and hearing protection. Once I’m geared up, I do a quick visual inspection of my grinder to make sure it’s in good working condition, and the safety guards are in place.

Next, I check the power cord and make sure it’s in good condition with no frays or cuts. I plug my grinder into a grounded electrical outlet and ensure that the power switch is in the “Off” position before starting.

With everything in order, I’m ready to power up my grinder. I turn on the switch, and the grinding wheels come to life. I take a moment to listen for any unusual noises or vibrations, as these could indicate a problem with the grinder.

2. Using the Grinder

With my grinder up and running, it’s time to put it to work. I hold the workpiece firmly with both hands and position it against the grinding wheel. I apply gentle pressure and let the wheel do the work. It’s essential to avoid forcing the workpiece into the wheel, as this can lead to kickback and loss of control.

As I’m grinding, I keep a close eye on the workpiece and the grinding wheel. I make sure that the workpiece remains in contact with the wheel at all times and that I’m grinding evenly across its surface. If I’m working with a larger workpiece, I move it back and forth to prevent excessive wear on one area of the wheel.

3. Stopping the Grinder

When I’m done grinding, I turn off the grinder by switching the power switch to the “Off” position. I wait for the grinding wheels to come to a complete stop before setting the workpiece aside. It’s essential not to leave the grinder unattended while the wheels are still spinning.

After I’ve stopped the grinder, I take a moment to inspect the workpiece and make sure it meets my desired specifications. I also check the grinding wheels for any signs of wear or damage. If the wheels need replacement or maintenance, I take care of it before my next grinding session.

Remember, safety doesn’t end when the grinder is turned off. I always unplug the grinder from the electrical outlet when it’s not in use. This prevents any accidental startups and ensures that my grinder is safely stored until the next time I need it.

By following these safe operating procedures, I can confidently and efficiently use my bench grinder while minimizing the risk of accidents and injuries. Safety is paramount in every workshop, and being vigilant during bench grinder operation is a non-negotiable part of my routine. So, with safety at the forefront, let’s continue making precision work with our bench grinders!

Post-Use Safety Measures

Ensuring safety doesn’t stop when I turn off my bench grinder. After every grinding session, I make it a habit to follow essential post-use safety measures. Taking the time to clean my work area and properly maintain my grinder not only prolongs its life but also ensures a safer environment for future use. Let’s dive into the two crucial post-use safety measures:

Cleaning the Work Area

The first step I take after using my bench grinder is to clean my work area thoroughly. Grinding can produce a significant amount of debris, dust, and metal shavings. Leaving these materials scattered around the work area poses potential hazards, from tripping over debris to inhaling harmful dust particles.

I start by sweeping or vacuuming the area around my grinder to remove any loose debris. Carefully collecting all the metal shavings and dust ensures that I don’t miss any hazardous particles. Next, I wipe down the workbench or table to get rid of any remaining dust and metal particles. I pay special attention to the areas surrounding the grinder to make sure there are no hidden shards or sharp objects.

As a safety-conscious individual, I take this cleaning process seriously, as it not only promotes a neat and organized workspace but also eliminates potential safety risks for myself and anyone else who might use the area in the future.

Maintaining the Grinder

Maintaining my bench grinder is key to its long-term performance and safety. After each use, I inspect the grinding wheels for any signs of wear or damage. The grinding wheels are the workhorses of my grinder, and ensuring they are in top-notch condition is crucial for safe and efficient grinding.

If I notice any chips, cracks, or uneven wear on the grinding wheels, I replace the affected wheel promptly. Using damaged or worn-out wheels can lead to dangerous incidents, such as wheel disintegration or loss of control during grinding. To prevent potential accidents during future use, I take no chances and always prioritize the safety of myself and others in the workshop.

Next, I check the tool rests and spark guards for any adjustments or repairs needed. Properly positioned tool rests ensure that I can control the workpiece effectively during grinding, while intact spark guards shield me from sparks and debris. I ensure that the tool rests are securely in place and properly aligned with the grinding wheels t o maintain optimal control and precision.

Additionally, I inspect the spark guards to confirm that they are free from any damage or obstructions. If any adjustments or repairs are necessary, I take care of them immediately, as any compromise in safety features can put me at risk during future bench grinder operations.

I also pay attention to my grinder’s overall condition, including its motor and electrical components. Regular maintenance and cleaning of my grinder’s exterior and internal parts are essential to keep it running smoothly and safely. I follow the manufacturer’s guidelines for maintenance and ensure that my grinder’s motor and electrical connections are in good condition.

If I notice any issues, strange noises, or abnormalities during operation, I address them promptly. If needed, I consult my grinder’s manual or seek professional assistance to diagnose and rectify any potential problems. My proactive approach to maintenance and safety ensures that my bench grinder remains a reliable and safe tool in my workshop.

By incorporating these post-use safety measures into my routine, I ensure that my work area remains hazard-free and that my bench grinder stays in top-notch condition. Safety is an ongoing commitment, and by taking these extra steps, I can continue enjoying the precision and efficiency that my bench grinder brings to my workshop. So, let’s always prioritize safety, both during and after using our bench grinders, for a rewarding and accident-free woodworking experience!

Common Mistakes to Avoid When Using a Bench Grinder

Using a bench grinder can be a rewarding experience when done safely and correctly. However, there are some common mistakes that even experienced users can make. Being aware of these mistakes and taking preventive measures can help ensure a safe and accident-free grinding session. Let’s explore these common safety mistakes and how to avoid them:

- Neglecting to Wear Safety Gear: As a safety-conscious tool enthusiast, I know the importance of protecting myself while operating a bench grinder. Safety glasses are a must-have to shield my eyes from flying debris and sparks. Sturdy work gloves offer protection against hot metal shards, while a dust mask safeguards my respiratory system from harmful dust particles. Hearing protection, like earplugs or earmuffs, shields my ears from the noise generated during grinding. Safety gear is my first line of defense against potential hazards, so I never compromise on it.

- Skipping Pre-Use Safety Checks: Before I power up my bench grinder, I take a moment to conduct a visual inspection. I carefully inspect the grinder for any signs of damage, such as cracks or chips on the grinding wheels. I also ensure that the power cord is in good condition with no frays or cuts. Checking that the safety guards are in place is essential, as these guards act as protective shields, preventing sparks and debris from flying towards me while I’m working. By taking the time for pre-use safety checks, I establish a safe foundation for my grinding session.

- Using Incorrect Wheel for the Task: I always double-check that I am using the appropriate grinding wheel for the material I am working on. Different materials require different wheel grits and compositions. By using the right wheel for the job, I achieve the best results and minimize the risk of accidents.

- Overlooking Workpiece Positioning: To ensure stability and precision during grinding, I take extra care in positioning the workpiece securely against the tool rest and the grinding wheel. Proper workpiece positioning allows me to maintain better control and achieve accurate results.

- Forcing the Workpiece into the Wheel: I apply gentle and even pressure to the workpiece and allow the grinder to do its job. This approach ensures a smoother grinding process and reduces the risk of accidents.

- Ignoring the Grinder’s Speed: I always check the grinder’s speed and match it to the requirements of the material I am grinding. This practice ensures optimal performance and extends the life of the grinding wheels.

- Failing to Use Proper Coolant: I make it a point to use the appropriate coolant or lubricant to keep the grinding process smooth and safe.

- Leaving the Grinder Unattended: I never leave the grinder unattended while it’s still running or has recently been turned off. It’s crucial to wait for the grinding wheels to come to a complete stop before setting the grinder aside. Additionally, I unplug the grinder from the electrical outlet when it’s not in use. This prevents any accidental startups and ensures that the grinder is safely stored until the next time I need it.

- Using Damaged or Worn-out Wheels: After each use, I inspect the wheels for any signs of wear or damage. Using well-maintained grinding wheels is essential for safe and efficient grinding.

- Grinding Inappropriately-Sized Materials: I use appropriate fixtures or holding devices for small or irregularly shaped materials to ensure safety and stability during grinding.

By being aware of these common mistakes and actively avoiding them, I ensure a safer and more efficient bench grinder operation. Prioritizing safety and adhering to best practices allow me to make the most of this powerful tool while minimizing the risk of accidents or injuries. Remember, safety is a continuous effort, and being cautious and well-informed is the key to a successful and enjoyable grinding experience. So, let’s stay vigilant and make safety a top priority in our workshop!

Suggested Reading: Things To Make With Lathe Wood Tools

FAQs: How to Use a Bench Grinder Safely

As I’ve covered the ins and outs of using a bench grinder safely, it’s time to address some common questions that many enthusiasts like us might have. Safety is our top priority, and being well-informed is key to a successful and accident-free woodworking experience. Let’s dive into these frequently asked questions and provide you with the answers you seek:

Is it necessary to wear safety gear while using a bench grinder?

Absolutely! Wearing the appropriate safety gear is a fundamental safety practice when operating a bench grinder. Safety glasses protect our eyes from flying debris and sparks, work gloves shield our hands from hot metal shards, dust masks safeguard our respiratory system, and hearing protection shields our ears from noise. Prioritizing safety gear is a non-negotiable aspect of bench grinder use.

Can I use any grinding wheel for all tasks?

No, using the correct grinding wheel for each task is essential. Different materials require specific wheel grits and compositions. For example, we should use a diamond wheel for grinding hard materials like carbide and an aluminum oxide wheel for ferrous metals. Using the wrong wheel can lead to inefficiency and potential accidents.

How often should I inspect and maintain my bench grinder?

Regular inspections and maintenance are crucial for our bench grinder’s performance and safety. After each use, we should inspect the grinding wheels for wear or damage, and replace any damaged wheels promptly. Checking the tool rests and spark guards for proper positioning and adjusting as needed is important. Following the manufacturer’s guidelines for maintenance and keeping the grinder’s motor and electrical connections in good condition are also essential.

Remember, safety is a continuous effort, and being well-informed about safe practices ensures that we make the most of our bench grinder while minimizing risks. Let’s prioritize safety and enjoy happy and safe grinding in our workshop!

Conclusion

As I wrap up our comprehensive guide on using a bench grinder safely, I want to emphasize the paramount importance of prioritizing safety in every step of our grinding process. Whether we’re seasoned pros or beginners just starting our journey in the world of tools, safety is a non-negotiable aspect that we should never take lightly.

Throughout this guide, I’ve discussed the essential safety gear, pre-use safety checks, safe operation practices, common mistakes to avoid, and post-use safety measures. Each of these aspects plays a vital role in creating a safe and accident-free environment in our workshops.

By wearing the appropriate safety gear, conducting pre-use safety checks, using the correct grinding wheel, positioning the workpiece correctly, and being cautious at every step, I significantly reduce the risk of accidents and injuries. Additionally, post-use safety measures, such as cleaning our work areas and maintaining our bench grinders, ensure that our workshops remain hazard-free, and our tools perform optimally.

As a fellow tool enthusiast and safety-conscious individual, I cannot stress enough the importance of cultivating safe practices in my workshops. Safety should never be an afterthought; it should be the foundation upon which every task is performed.

Let’s always prioritize wearing the proper safety gear, even for the simplest grinding tasks. We must take the time for pre-use safety checks to establish secure and hazard-free workspaces. Using the appropriate grinding wheel for each task and never forcing the workpiece into the wheel is essential for our safety. We should remember to monitor the speed of our grinders and use proper coolant when grinding metals.

Furthermore, let’s never leave our bench grinders unattended, and always unplug them from the electrical outlet when they’re not in use. Regularly inspecting our grinding wheels for wear and damage and promptly replacing any damaged wheels is crucial for our safety.

By adopting these safe practices, we not only protect ourselves but also set a positive example for others in our workshops. Safety is a shared responsibility, and by promoting safe practices, we contribute to a culture of well-being and productivity.

Using a bench grinder can be a rewarding and efficient experience when approached with the right knowledge, skill, and most importantly, a commitment to safety. By following the guidelines outlined in this guide and being vigilant in our approach, we can make the most of this versatile tool while ensuring a safe and accident-free woodworking experience.

So, my fellow tool enthusiasts, let’s continue embracing safety as an integral part of our workshop routines. Let’s prioritize the well-being of ourselves and those around us. Remember, each grinding session is an opportunity to create something exceptional, and by doing it safely, we can achieve precision, efficiency, and fulfillment in our woodworking endeavors. Happy and safe grinding!

More Bench Grinder Resources:

Since You’re Here Check Out Some More Bench Grinder Based Posts I Wrote