The 3 Best Drill Bits For Ceramic Pots

Ceramic pots have gained immense popularity in the realm of gardening and interior design. I absolutely love how these elegant and versatile pots add a touch of sophistication to any space. However, I understand that drilling holes in ceramic pots can be quite challenging and requires the use of the best drill bits for ceramic pots. In this article, we will delve into the fascinating world of drill bits specifically designed for ceramic pots.

Together, we will explore their significance in promoting healthy plant growth, enhancing drainage, and preventing issues like waterlogging and root rot. Let’s embark on this journey to discover the perfect drill bits for your ceramic pots!

Understanding Ceramic Pots

Ceramic pots are crafted from various materials, such as clay, terracotta, porcelain, or stoneware. These materials offer exceptional durability and strength, ensuring that your plants are supported in a stable and secure environment. Moreover, ceramic pots come in a wide range of sizes, shapes, and colors, allowing you to choose the perfect vessel that complements your aesthetic preferences.

Why Drill Holes in Ceramic Pots?

Promoting Healthy Plant Growth

Drilling holes in ceramic pots is crucial for the well-being of your plants. Adequate drainage is vital to prevent water from stagnating in the pot, which can lead to root rot and other moisture-related issues. By providing an outlet for excess water, you create an optimal environment for the roots, promoting healthy growth and preventing waterlogged soil.

Improving Drainage

Effective drainage is essential for maintaining the right moisture levels in the soil. Without proper drainage, water accumulates at the bottom of the pot, causing the soil to become oversaturated. This can deprive the roots of oxygen and lead to root diseases. By drilling holes, you ensure that excess water can escape, allowing the soil to remain well-drained.

Preventing Waterlogging and Root Rot

Waterlogging is a common issue in ceramic pots without drainage holes. Excessive water retention can suffocate the roots, leading to root rot, which can be detrimental to plant health. By incorporating drainage holes, you prevent water from accumulating, reducing the risk of root rot and promoting a healthier root system.

Types of Drill Bits for Ceramic Pots

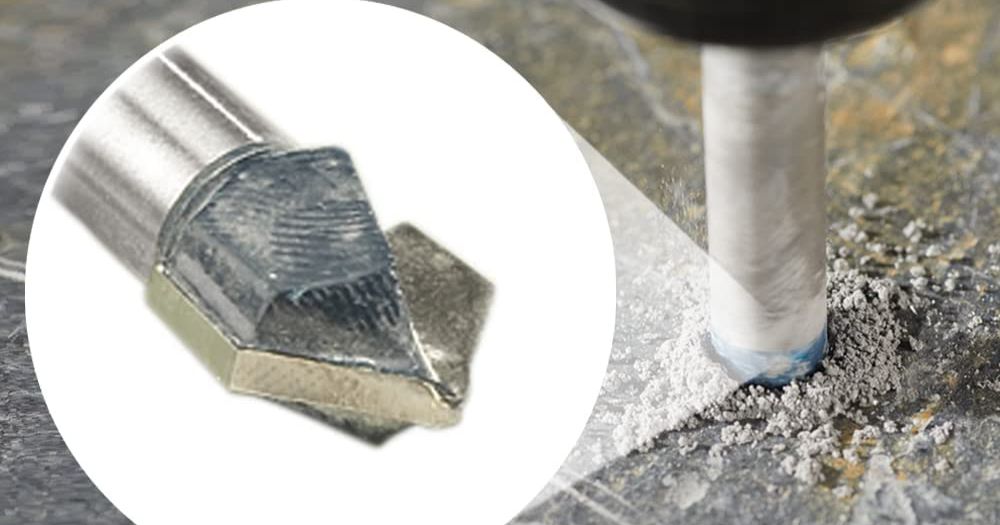

A. Diamond-Coated Drill Bits

Diamond-coated drill bits are specifically designed for drilling through hard materials like ceramic. The diamond coating enhances their durability and cutting performance, allowing them to effortlessly penetrate the tough surface of ceramic pots. The diamond particles provide a superior cutting edge, ensuring clean and precise holes.

| # | Image Preview | Product | Rating |

|---|---|---|---|

| 1 |  | BOSCH NS2000 | 4.5/5 |

| 2 |  | DEWALT Masonry Drill Bit Set, | 4/5 |

| 3 |  | QWORK 5 Pcs Multi-Material Drill Bit Set | 3/5 |

Explanation of Diamond-Coating Technology

Diamond-coating technology involves the application of microscopic diamond particles to the drill bit’s surface. This coating creates an incredibly hard and abrasion-resistant layer that enhances the drill bit’s performance and extends its lifespan.

Benefits of Diamond-Coated Drill Bits

Diamond-coated drill bits offer several advantages:

- Exceptional durability and longevity

- High precision and accuracy in drilling holes

- Reduced heat generation during drilling

- Suitable for both small and large drilling projects

B. Carbide-Tipped Drill Bits

Carbide-tipped drill bits are another excellent option for drilling ceramic pots. These bits are made from a combination of tough steel and carbide, a hard and wear-resistant material. The carbide tip provides superior cutting power, making it easier to penetrate the ceramic surface.

Overview of Carbide-Tipped Technology

Carbide-tipped drill bits are constructed with a steel body and a carbide insert on the tip. The carbide insert, often in the form of a small point or cutting edge, enhances the drilling capability of the bit and ensures longevity.

Maybe its time to get a new Impact Driver Drill. Check out the Best Impact Driver Drill Under $100.

Advantages of Carbide-Tipped Drill Bits

Carbide-tipped drill bits offer several advantages:

- Excellent cutting performance and efficiency

- Enhanced durability and resistance to wear

- Reduced heat generation during drilling

- Suitable for drilling larger holes

C. Porcelain or Glass Drill Bits

For delicate ceramic pots, such as porcelain or glass, specialized drill bits are available. These bits are designed to minimize the risk of cracking or damaging the fragile material while still providing efficient drilling capabilities.

Specialized Drill Bits for Delicate Ceramics

Porcelain or glass drill bits feature a unique design that reduces the likelihood of chipping or breaking the ceramic surface. They often incorporate a spear-shaped tip or a diamond-coated edge, allowing for precise and controlled drilling.

Unique Features of Porcelain or Glass Drill Bits

Porcelain or glass drill bits offer distinct features:

- Gentle and controlled drilling to prevent damage

- Specialized designs to accommodate fragile ceramics

- Suitable for drilling smaller holes

Choosing the Right Drill Bit

When selecting a drill bit for ceramic pots, consider the following factors:

A. Consider the Pot Material

Different ceramic materials may require specific drill bits. Ensure that the drill bit you choose is compatible with the type of ceramic pot you have.

B. Determine the Hole Size Needed

Evaluate the size of the hole you need to drill. This will help you determine the appropriate drill bit size required for the job.

C. Assess the Drill Type and Power

Consider the type of drill you will be using. Some drill bits are designed for use with standard power drills, while others may require specialized equipment. Additionally, assess the power of your drill to ensure it can handle the drilling task effectively.

D. Research and Read Product Reviews

Before making a purchase, conduct thorough research and read product reviews. This will help you gather insights from other users who have experience with different drill bits, allowing you to make an informed decision.

Preparing the Ceramic Pot

Before drilling into your ceramic pot, it’s essential to prepare the pot and create a safe and efficient drilling environment. Follow these steps:

A. Safety Precautions

Always prioritize safety when working with power tools. Wear protective gear such as safety goggles and gloves to safeguard yourself from any potential hazards.

B. Selecting the Drilling Spot

Choose the ideal spot on the ceramic pot where you want to drill the hole. Consider the overall design and functionality of the pot, as well as the specific requirements of your plants.

C. Marking the Drilling Point

Once you have selected the drilling spot, mark it with a pencil or a marker. This will help guide the drill bit and ensure accuracy during the drilling process.

D. Securing the Pot for Drilling

To prevent the pot from moving or slipping during drilling, secure it in place. You can use clamps or ask someone to hold the pot steady while you operate the drill. This will ensure stability and minimize the risk of accidental slips or cracks.

Drilling Techniques for Ceramic Pots

Drilling holes in ceramic pots requires proper technique to achieve clean and precise results. Follow these guidelines for successful drilling:

A. Starting with a Pilot Hole

To avoid potential cracks or chips, start by creating a small pilot hole. This will serve as a guide for the larger drill bit and prevent the ceramic from fracturing under pressure.

B. Applying Consistent Pressure

Maintain a steady and consistent pressure while drilling. Avoid excessive force, as it can cause the ceramic to crack. Let the drill bit do the work, and allow it to cut through the material at its own pace.

C. Using Water or Lubricant as a Coolant

To prevent overheating and damage to the ceramic pot, use water or a lubricant as a coolant during the drilling process. Apply a small amount to the drilling spot to keep the temperature down and ensure smoother drilling.

D. Taking Breaks to Avoid Overheating

Drilling through ceramic generates heat, which can affect the integrity of the material. Take regular breaks during the drilling process to allow the ceramic to cool down. This will prevent excessive heat buildup and minimize the risk of cracks or damage.

Caring for Ceramic Pots after Drilling

After successfully drilling holes in your ceramic pot, it’s important to properly care for it to maintain its aesthetics and functionality. Follow these steps:

A. Cleaning the Pot

Clean the pot to remove any debris or residue from the drilling process. Use a soft brush or cloth to gently wipe away any dirt or particles, ensuring the pot is clean and ready for use.

B. Smoothing Rough Edges

If there are any rough or uneven edges around the drilled hole, use sandpaper or a grinding tool to smooth them out. This will prevent any potential injuries and give the pot a neater appearance.

C. Applying Sealant, if Desired

Optionally, you can apply a sealant around the drilled hole to further protect the ceramic and create a watertight seal. Choose a sealant specifically designed for ceramics, following the manufacturer’s instructions for application.

Troubleshooting Common Issues

Sometimes, issues may arise during the drilling process. Here are some common problems and their potential solutions:

A. Pot Cracking During Drilling

If you experience cracking while drilling, it could be due to excessive pressure or improper drilling technique. To prevent further damage, stop drilling immediately and assess the situation. Consider using a smaller drill bit or consulting a professional if necessary.

B. Drill Bit Slipping or Getting Stuck

If the drill bit slips or gets stuck in the ceramic pot, carefully remove the drill and assess the situation. Check for any obstructions or issues with the drill bit itself. Ensure the pot is securely positioned and try again with a steady hand and proper technique.

C. Repairing Cracked or Damaged Pots

In the unfortunate event of a cracked or damaged pot, you can explore repair options. Depending on the extent of the damage, you can use ceramic adhesives or consult a professional for more complex repairs. Assess the feasibility of repair versus replacing the pot.

Alternatives to Drilling

If you prefer not to drill holes in your ceramic pot, there are alternative solutions available:

A. Adhesive-Based Solutions

Various adhesive-based products, such as adhesive pads or strips, are designed to provide temporary drainage solutions for ceramic pots. These can be attached to the base of the pot, allowing water to drain without permanent modifications.

B. Self-Watering Systems

Self-watering systems offer a convenient alternative to drilling holes. These systems have built-in reservoirs that allow plants to draw water as needed, reducing the risk of overwatering and eliminating the need for drainage holes.

C. Utilizing Removable Inserts

Removable inserts, such as nursery pots or plastic liners, can be placed inside the ceramic pot to create a separate drainage system. These inserts can be easily removed for watering and cleaning, providing a flexible and adaptable solution.

1. BOSCH NS2000

Experience superior value for your money with the BOSCH NS2000. Engineered with the highest standards of durability in mind, this product is a testament to BOSCH’s commitment to long-lasting quality. The NS2000 is designed to withstand daily wear and tear, making it a resilient choice that is worth every penny. Its longevity is one of its standout features, as it effortlessly outperforms other models in its lifespan. With the BOSCH NS2000, you’re not just making a purchase, you’re making a long-term investment. This is an item that’s crafted to stand the test of time, eliminating the need for frequent replacements. Choose the BOSCH NS2000, the perfect blend of affordability, robust durability, and impressive longevity. It’s the intelligent choice for discerning customers who appreciate both performance and longevity in their investments.

Pros

- Accuracy

- No Water Required

- Special Carbide Tip

Cons

- Get Dull Fast

2. DEWALT Masonry Drill Bit Set,

Discover unparalleled value with the DEWALT Masonry Drill Bit Set, Percussion. This robust set, noted for its outstanding durability, withstands intense masonry work while ensuring long-term use. The set’s impressive longevity, combined with its affordability, makes it a wise investment for the cost-conscious and performance-driven user. Experience DEWALT’s marriage of durability and longevity, and make your masonry work more efficient and reliable.

Pros

- Longer bit life

- Efficient drilling

- 2 cutter carbide tip

Cons

- Packaging is junk

3. QWORK 5 Pcs Multi-Material Drill Bit Set

Make your work easier with the QWORK 5 Pcs Multi-Material Drill Bit Set. This user-friendly set offers excellent value for money, combining affordability with high-performance. Constructed for durability, each bit is designed to withstand various material applications, providing a reliable toolset that lasts. Choose QWORK for a convenient, cost-effective, and robust solution for your drilling needs.

Pros

- Sturdiness

- Heavy duty drill bits

- Accuracy

Cons

- Coating comes off the tip

FAQs: Best Drill Bits for Ceramic Pots

Got a burning curiosity about drill bits for ceramic pots? I’ve got you covered! I’ve gathered together some frequently asked questions that should satisfy your need for answers. So, strap in and read on, let’s learn more together!

What type of drill bit should I use for drilling ceramic pots?

When it comes to drilling ceramic pots, using the right drill bit is crucial. For optimal results, consider diamond-coated drill bits or carbide-tipped drill bits. Diamond-coated drill bits are known for their durability and precision, making them ideal for drilling through tough ceramic surfaces. On the other hand, carbide-tipped drill bits offer excellent cutting power and are suitable for both small and large drilling projects. Choose a drill bit that matches your specific needs and the type of ceramic pot you are working with.

How do I drill holes in ceramic pots without cracking them?

Drilling holes in ceramic pots can be tricky, as there is always a risk of cracking or damaging the material. To minimize this risk, follow these tips:

Start with a pilot hole: Begin by creating a small pilot hole as a guide for the larger drill bit. This helps prevent the ceramic from fracturing under pressure.

Apply consistent pressure: Use a steady hand and apply a consistent, controlled pressure while drilling. Avoid excessive force, as it can lead to cracks.

Use water or lubricant as a coolant: To prevent overheating, use water or a lubricant as a coolant during the drilling process. Apply a small amount to the drilling spot to keep the temperature down and ensure smoother drilling.

Take breaks: Allow the ceramic to cool down by taking regular breaks during the drilling process. This helps prevent excessive heat buildup and reduces the risk of cracks or damage.

Can I use regular drill bits for ceramic pots?

Regular drill bits may not be suitable for drilling ceramic pots due to their design and materials. Ceramic is a hard and brittle material that requires specialized drill bits for efficient drilling without causing damage. Regular drill bits may not have the necessary cutting power or durability to penetrate the ceramic surface effectively. It’s recommended to invest in diamond-coated or carbide-tipped drill bits specifically designed for drilling through ceramics. These specialized drill bits offer better performance, precision, and longevity, ensuring successful drilling without compromising the integrity of the ceramic pot.

Suggested Reading: Best Glass Drill Bits

And The Best Drill Bit for Ceramic Pots Is..

I recommend the BOSCH NS2000 drill bit for the fact that you don’t need any water or coolant to successfully drill a hole in a ceramic flower pot.

Drill bits for ceramic pots, in my experience, are game-changers when it comes to caring for plants and adding your personal touch. By drilling holes, we’re not just making our pots look good – we’re promoting healthier plant growth, boosting drainage, and preventing waterlogging and root rot. And from my toolkit, diamond-coated drill bits, carbide-tipped drill bits, and porcelain or glass drill bits are some great options to consider.

When I pick the right drill bit, prep my ceramic pot carefully, and apply the right drilling techniques, I’ve found that I can create clean, precise holes without any damage to the pot. After drilling, taking care of the pot is vital, as is troubleshooting common issues. And hey, if drilling doesn’t float your boat, don’t worry! There are other solutions to explore too. So, with the right tools and techniques in your arsenal, you too can create a perfect home for your plants and give your ceramic pots a sprinkle of your own personal style. Happy drilling and pot customization, folks!