How To Set up A Portable Dust Collection System In A Woodshop

Woodworking, a passion and craft that I’ve always held close to my heart, has its own set of challenges and nuances. One of the pivotal aspects that often gets overshadowed in the excitement of creating something new is the imperative need for a clean and safe working environment. That’s where understanding how to set up a portable dust collection system in a woodshop becomes not just a need but a quintessential component of our woodworking journey.

As I dove deeper into the woodworking world, the subtle art of managing wood dust became glaringly apparent. It’s not merely about keeping the space clean; it’s about safeguarding our health, ensuring every crafted piece is impeccable, and prolonging the life of our cherished tools. The fine particles of wood dust, almost invisible to our eyes, can be a silent adversary, impacting not only our health but also the quality of our work.

Setting up a portable dust collection system in my woodshop was a revelation. It was about taking those extra steps to ensure that every minute spent in my workshop was safe, efficient, and thoroughly enjoyable. The tranquility that comes with a well-organized, dust-free space is unparalleled and allows the creativity to flow unhindered.

In this journey together, I’ll share the insights, the why’s, and the how’s of establishing an efficient portable dust collection system in a woodshop, ensuring that we not only create beautifully but also do so in a space that speaks of safety, health, and impeccable craftsmanship. Let’s embark on this journey to create not just with our hands, but to do so in an environment that takes care of us as much as we do of it.

How to Set Up a Portable Dust Collection System: A Step-by-Step Guide

The journey of woodworking is not merely about crafting beautiful pieces but also about ensuring that the space where creativity blossoms is conducive, safe, and efficient. This is where learning how to set up a portable dust collection system in a woodshop becomes an integral chapter of our woodworking story. It’s not just about cleanliness; it’s about creating a sanctuary where our creations come to life without being hindered by the pervasive wood dust.

Embarking on this journey, I realized that setting up a dust collection system was not merely about installing a machine but understanding the dynamics of my workspace, ensuring that every corner was accounted for, and every breath I took was clean and safe.

Selecting the Right Dust Collector and Accessories

My first step into establishing a dust-free workshop was choosing the right dust collector. It was a decision that demanded consideration of various aspects like the CFM (Cubic Feet per Minute) rating, which essentially determined the efficiency of the system in managing the dust produced in the workshop. Power, size, and compatibility with my workspace were other pivotal factors that played a crucial role in the decision-making process.

Exploring the aisles of dust collectors, I found myself amidst a myriad of options, each promising to be the sentinel of cleanliness in my workshop. But understanding my space, the volume of dust produced, and the intricacies of my work became the guiding light, leading me to a choice that resonated with my needs.

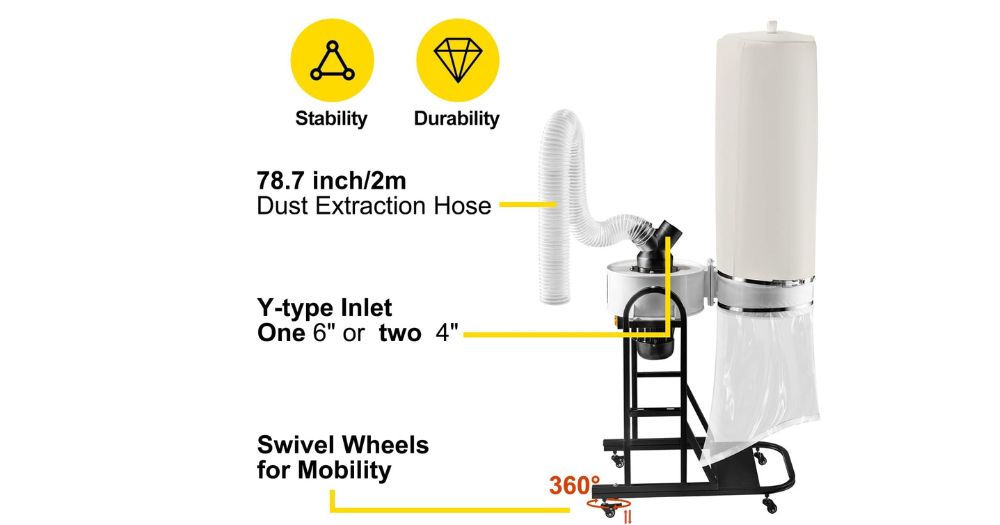

Accompanying the dust collector, accessories like hoses, fittings, and filters became the silent heroes, ensuring the efficiency of the dust collection system. The hoses needed to be of a caliber that could handle the volume and type of dust produced, while the fittings ensured that the system was seamlessly integrated into my workspace. Filters, the guardians of air quality, were chosen with meticulous attention, ensuring that even the finest particles were captured, safeguarding not just the workshop but also my health.

Ensuring Optimal Air Flow and CFM Rating

Understanding and ensuring optimal airflow and maintaining the right CFM rating was the next chapter in my journey. It was not merely about installing the system but ensuring that it operated with utmost efficiency. The path of the airflow, the turns in the ductwork, and the distance it traveled – each aspect played a pivotal role in determining the efficiency of the dust collection system.

Ensuring short runs and minimal turns in the ductwork, I realized, was not just about efficiency but also about maintaining the integrity of the system, reducing the wear and ensuring longevity. The CFM rating, on the other hand, became a measure of ensuring that the system was capable of handling the volume of dust produced, ensuring that no particle was left unaccounted for.

As we navigate through the subsequent sections, I’ll share the detailed steps, the considerations, and the nuances of setting up a portable dust collection system in a woodshop, ensuring that the sanctuary where our creations come to life is respected, cherished, and maintained, just like every piece that is born within its confines.

Suggested Reading: The 5 Best Band Saws Under $500

Suggested Reading: The 7 Best Miter Saws for Furniture Making

Exploring Types of Dust Collection Systems

Embarking on the journey of establishing a dust-free workshop, I found myself amidst a plethora of options when it came to dust collection systems. It was like stepping into a world where each system promised to be the guardian of my workshop, ensuring every particle of dust was accounted for. But as we know, every woodshop is unique, and understanding the nuances of various dust collection systems became my mission, ensuring that the chosen guardian was indeed the right fit for my space.

In my quest, keywords like single-stage and two-stage dust collectors, dust extractors, and specific models like the Dust RIGHT 1250 cfm Dust Collector became frequent visitors in my research. Each term opened up a new perspective, a new approach towards managing wood dust effectively and efficiently.

Single-Stage vs. Two-Stage Dust Collectors

Navigating through the realms of dust collectors, I found myself amidst a pivotal decision – choosing between single-stage and two-stage dust collectors. It was a choice that needed a deep dive, understanding the intricacies, the pros, and the cons of each type.

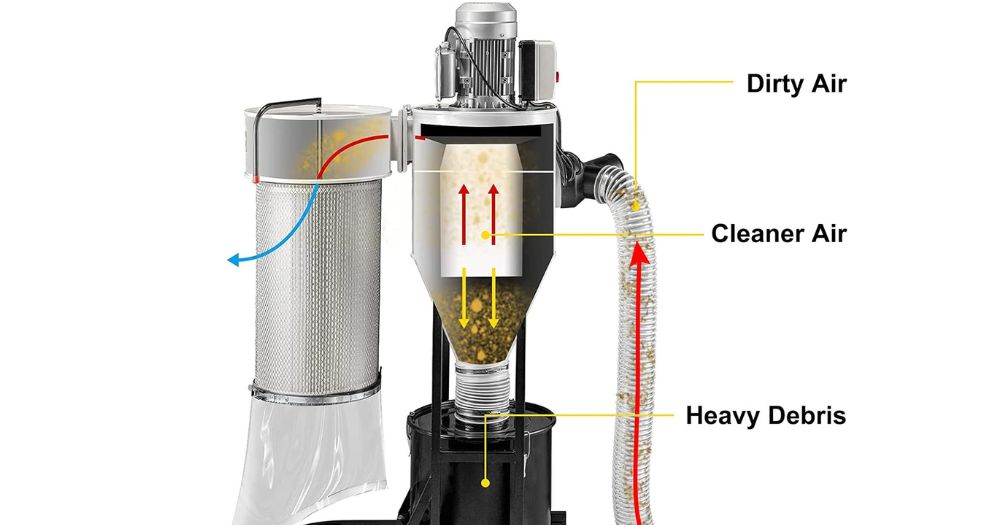

In the world of single-stage dust collectors, simplicity took the forefront. Here, the system sucked up the dust, directing it straight into a collection bag or bin. The straightforward mechanism was indeed appealing, offering ease of use and maintenance. But every coin has two sides, doesn’t it? The single-stage collector, while being efficient with larger dust particles, often fell short when it came to the finer, more harmful dust, allowing them to escape back into the workshop.

On the other hand, the two-stage dust collectors presented themselves as the meticulous cleaners. The process involved an initial separation stage, where the larger dust particles were deposited into a collection bin. The finer particles were then directed to a filter, ensuring that even the most minute of adversaries were captured. It was a system that promised thoroughness but also came with its own set of complexities in terms of setup and maintenance.

As I weighed the pros and cons, considering factors like space, budget, and the nature of my projects, the choice between single-stage and two-stage became a reflection of my workshop’s unique needs. It was a realization that there was no one-size-fits-all, but rather a solution that resonated with the rhythm of my woodworking journey.

In the sections to follow, let’s delve deeper into the specifics, understanding the mechanisms, and exploring the world of dust collection together, ensuring that our workshops are not just spaces of creation, but also sanctuaries that safeguard our health and passion.

Watch This Video And Learn About How To Set up A Portable Dust Collection System In A Woodshop

Health and Safety Protocols in Managing Wood Dust

In the midst of shavings, sawdust, and the rhythmic hum of the machines, I found solace and a sense of unbridled creativity within the walls of my woodshop. But beneath the surface of this serene creation space, I recognized an often-overlooked aspect – the silent, invisible threat posed by wood dust. It was a realization that brought forth not just an understanding but a responsibility towards establishing health and safety protocols in managing wood dust.

Navigating through the sawdust, I realized that the particles, so minute, so inconspicuous, were not merely residues of my creation but potential hazards that could permeate my being, affecting my health and well-being. Safety, I realized, was not just about the immediate, visible threats but also about managing and mitigating the unseen, ensuring that every breath within the workshop was as pure as the passion that drove my creations.

Ensuring safety while managing wood dust became a journey of understanding, planning, and meticulous implementation. It was about recognizing the areas where dust could accumulate, the points where it was generated the most, and ensuring that at each of these points, the dust was managed and contained effectively.

A well-planned dust collection system thus became the backbone of maintaining a healthy woodworking environment. It was not merely a tool but a companion that safeguarded me, ensuring that my journey through woodwork was not hindered by potential health risks. The system ensured that the dust, once created, was immediately captured, not allowing it to become a pervasive entity within the workshop.

But the responsibility did not end with the installation of a dust collection system. It extended into ensuring that the system was maintained, that the filters were regularly checked and replaced, and that every nook and corner of the workshop adhered to the health and safety protocols that were established.

In the subsequent sections, I’ll delve deeper into the nuances, the considerations, and the meticulous planning involved in establishing and maintaining health and safety protocols in managing wood dust. Together, let’s ensure that our spaces of creation are sanctuaries of not just creativity but also safety and well-being.

Maintenance and Upkeep of a Dust Collection System

As the sawdust gently settled after a day of crafting in my beloved woodshop, I gazed at my dust collection system, a silent sentinel that had tirelessly worked to keep my space clean and my air pure. It dawned on me that this guardian, while robust, also needed care, a reciprocation of the protection it provided me and my workshop. The journey into maintaining and ensuring the upkeep of a dust collection system unfolded, revealing layers that were as crucial as the system itself.

The dust collection system, while a formidable ally in keeping the workshop dust-free, demanded a meticulous routine of maintenance and upkeep. It wasn’t merely a set-and-forget apparatus; it was a dynamic entity that needed regular checks, optimizations, and sometimes, a gentle pat of appreciation for the relentless work it performed.

My first step into ensuring the optimal performance of the dust collection system was understanding its components, its filters, ducts, and collection units, each playing a pivotal role in maintaining the sanctity of the workshop. The filters, the first line of defense against the pervasive dust, needed regular checks and replacements, ensuring that they were always at their peak performance, capturing even the finest particles with ease.

The ducts, the pathways that guided the dust away from my workspace, needed to be devoid of any blockages, ensuring a smooth, unhindered flow of the dust from the source to the collection unit. A routine check, ensuring that the ducts were sealed and the pathways clear, became a small yet significant step in maintaining the efficiency of the system.

And then came the collection unit, the final resting place of the dust. Ensuring that it was emptied and cleaned at regular intervals ensured that the system was always ready, always prepared to handle the dust generated during my woodworking endeavors.

But maintenance and upkeep were not merely physical; it was also about understanding and sometimes, tweaking the system to ensure that it adapted to the evolving dynamics of my workshop. It was about ensuring that as my projects grew, as my workshop evolved, the dust collection system evolved with it, always providing optimal, unwavering support.

In the sections to follow, I will share the detailed, nuanced practices that have ensured that my dust collection system remains an unyielding protector of cleanliness and purity in my workshop. Let’s navigate through the intricacies together, ensuring that our workshops are not just spaces of creation but also epitomes of safety, cleanliness, and well-being.

FAQ Section: Navigating Through the Dust-Free Woodworking Journey

Embarking on a journey towards establishing a dust-free woodworking environment often brings forth a myriad of questions, curiosities, and sometimes, uncertainties. In this section, we delve into some of the frequently asked questions, aiming to shed light on the common queries and concerns that might flutter through your mind as you navigate through your dust-free woodworking journey. Let’s explore together, ensuring that every step taken is informed, confident, and in the right direction.

How often should I clean or replace the filters in my dust collection system?

The frequency of cleaning or replacing filters in your dust collection system largely depends on the usage and the type of woodworking projects undertaken. Regular checks are recommended to ensure optimal functionality. Typically, a visual inspection every month to assess any visible dust accumulation or decrease in suction power can be a good practice. However, if you engage in heavy woodworking tasks daily, more frequent checks might be necessary to ensure the system is operating efficiently and maintaining a healthy environment in your workshop.

Can a portable dust collection system handle all sizes of wood particles effectively?

While a portable dust collection system is designed to manage wood particles and maintain a cleaner air quality, the efficacy in handling different sizes of particles can depend on the system’s design, filter type, and CFM rating. Most systems can effectively manage larger wood shavings and medium-sized particles. However, for finer particles, a system with a higher CFM rating and a filter designed to capture microscopic particles is essential to ensure comprehensive dust management.

How do I determine the appropriate CFM rating for my woodshop?

Determining the appropriate Cubic Feet per Minute (CFM) rating for your woodshop involves considering several factors, including the size of your workshop, the type and number of woodworking machines used, and the overall dust generation. A general guideline is to have a dust collection system that offers enough CFM to handle all the machines that might be used simultaneously. Each woodworking machine typically has a recommended CFM which can be found in the user manual or manufacturer’s guidelines. Summing up the CFM requirements of the machines and considering the layout and size of the ductwork will help determine the appropriate CFM rating for your woodshop.

Navigating through the woodworking journey, your queries and concerns are always welcomed and valued. Should you have more questions or need further insights, feel free to reach out, ensuring that your path towards a clean, safe, and inspiring woodworking environment is always well-informed and thoroughly supported.

Conclusion: How To Set up A Portable Dust Collection System In A Woodshop

As I sweep my fingers across the smooth, dust-free surfaces of my workshop, a sense of tranquility envelops me. The journey through understanding, implementing, and maintaining a portable dust collection system in my woodshop has been enlightening, revealing that the essence of woodworking is not just in the creations but also in the environment in which they are crafted.

Reflecting upon the steps, the meticulous planning, and the understanding that unfolded in setting up a portable dust collection system, I realize that it was not merely an addition to the workshop but a transformation of it. It was about ensuring that every particle of dust was accounted for, that the air I breathed was as pure as the passion that flowed through each creation.

The importance of a clean, safe, and efficient woodworking environment cannot be overstated. It’s a sanctuary where our creations come to life, where our ideas transform into tangible entities. Ensuring that this space is respected, maintained, and cherished is as crucial as the creations that emerge from it.

As we navigated through the types of dust collectors, understood the nuances of airflow and CFM ratings, and delved into the meticulous maintenance of the system, it was a journey of ensuring that our health, our creations, and our passion were always in a space that nurtured and protected them.

My fellow woodworkers, the steps towards a clean, safe, and efficient workshop are not just procedures but a homage to our craft, our art, and ourselves. It’s a commitment to ensuring that our creativity is not hindered by the invisible threats that loom within the woodshop. It’s a pledge to ensure that every moment within the workshop is safe, healthy, and thoroughly enjoyable.

Let’s carry forward this understanding, ensuring that our workshops are not just physical spaces but sanctuaries that respect and nurture our craft. May every woodshop be a haven of creativity, unburdened by the perils of dust, and may every woodworker breathe in an environment that is as pure, safe, and inspiring as their creations.

Join the Journey, Share the Stories, and Let’s Craft Safely Together

As I lay down my tools, pausing to admire the dust-free ambiance of my workshop, I extend an invitation to you, my fellow artisans, to join me in this enlightening journey towards a clean, safe, and inspiring woodworking environment. Your experiences, your stories, and your insights are not just welcomed, but eagerly awaited, for every story adds a new perspective, a new learning to our collective woodworking journey.

Have you embarked on your journey towards establishing a dust-free workshop? Have there been challenges, triumphs, or unexpected learnings along the way? Your stories could be the beacon of light for a fellow woodworker, guiding them through their journey, offering insights and camaraderie in this beautiful path of creation.

👉 Share Your Story: Dive into the comments section below and let your experiences flow, allowing them to weave into the tapestry of collective knowledge and shared passion.

Your journey, your experiences are the threads that enrich our community, offering support, insights, and sometimes, a gentle nudge of inspiration to fellow woodworkers. Let’s continue to craft, create, and carve, ensuring that our workshops are sanctuaries of safety, health, and unbridled creativity.

🛠️ Together, let’s create beautifully, let’s create safely, and let’s share our stories, ensuring that every woodworker finds their path towards a clean, safe, and inspiring workshop. 🛠️