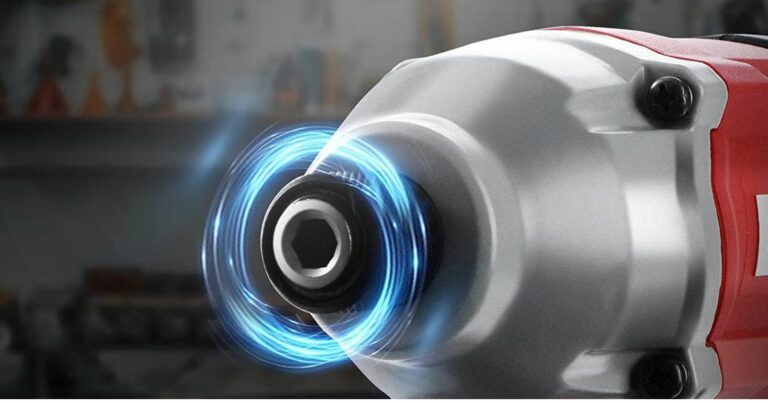

Why Impact Driver Drill Don’t Work In Cold Weather

As a contractor, I heavily rely on my impact driver drill to get the job done. However, when the temperature drops, I often find that my trusty tool doesn’t work as well as it should. In this post, I will discuss why my impact driver drill may not work in cold weather and what I can do to prevent and troubleshoot these problems.

How Cold Weather Affects Impact Driver Drills

Cold weather can have a significant impact on the performance of your impact driver drill. Here are some ways that cold temperatures can affect your tool:

Battery Life:

The cold weather can significantly reduce the life of your drill’s battery. When lithium-ion batteries are exposed to extreme cold, the chemical reactions within the battery slow down, reducing its capacity. This can result in a shorter runtime, reduced power output, and even complete battery failure.

Motor Performance:

The cold weather can also affect the performance of your drill’s motor. As the temperature drops, the motor’s lubrication thickens, causing the motor to work harder to turn. This can lead to a reduced power output and a shorter lifespan for the motor.

Lubrication:

Cold weather can also cause the lubrication in your drill’s moving parts to thicken, making them more difficult to move. This can cause increased wear and tear on the tool’s components and reduce the tool’s overall performance.

Watch This Video And Learn Why Impact Driver Drill Don’t Work In Cold Weather

Maybe its time to get a new impact driver. Check out the Best Impact Driver Drill Under $100.

Common Problems with Impact Driver Drills in Cold Weather

If you’re experiencing issues with your impact driver drill in cold weather, you’re not alone. Here are some common problems that contractors face:

Difficulty Starting the Drill:

The cold weather can make it challenging to start your drill, especially if it’s been stored in a cold garage or truck overnight.

Reduced Power Output:

As we mentioned earlier, the cold weather can reduce the power output of your drill’s motor and battery, making it more challenging to drive screws and drill holes.

Battery Draining Quickly:

If your drill’s battery is not holding a charge in cold weather, you may find that it drains quickly, reducing the tool’s overall runtime.

Strange Noises or Vibrations:

In extreme cases, the cold weather can cause your drill to make strange noises or vibrations. This could be a sign of motor damage, which may require professional repair.

Preventing Impact Driver Drill Problems in Cold Weather

The best way to prevent issues with your impact driver drill in cold weather is to take preventive measures. Here are some tips to help you maintain your tool’s performance:

Storing the Drill in a Warm Place

To prevent the battery and motor from being exposed to extreme cold, store your drill in a warm place, like inside your home or office.

Using a Lithium-Ion Battery:

Lithium-ion batteries are more resistant to cold weather than other types of batteries. If you’re using a different type of battery, consider upgrading to a lithium-ion battery.

Keeping the Drill’s Moving Parts Lubricated:

Regularly lubricating your drill’s moving parts can help prevent the lubrication from thickening in cold weather.

Checking the Drill’s Cords and Connections:

Check the cords and connections on your drill for signs of wear and tear. Cold weather can make them more brittle and prone to cracking, which can cause the tool to malfunction.

Troubleshooting Tips for Impact Driver Drill Problems in Cold Weather

- If you’re still experiencing issues with your impact driver drill in cold weather, here are some troubleshooting tips to help you get back to work:

Checking the Battery Charge:

Make sure your drill’s battery is fully charged before using it in cold weather.

Pre-Warming the Battery:

Before using your drill in cold weather, try pre-warming the battery by placing it in a warm location for a few minutes.

Using a Heated Jacket or Blanket:

Some manufacturers sell heated jackets or blankets designed to keep your tools warm in cold weather. These can be helpful in extreme cold conditions.

Keeping Spare Batteries Warm:

If you’re using multiple batteries, keep the spare batteries warm by storing them in a warm location until you need them.

Professional Repair:

If your drill is still not working correctly, you may need to take it to a professional for repair. It’s always better to have a qualified technician look at your tool rather than risking further damage by trying to fix it yourself.

My Experience and Others with Impact Driver Drills in Cold Weather

In this section, I’d like to share not only my personal experiences but also those of other professionals who regularly use impact driver drills in cold weather. Over the years, I’ve found that hearing from those who are in the trenches, so to speak, can provide invaluable insights.

As someone who has often found myself working in chilly conditions, I’ve had my fair share of struggles with impact driver drills. I’ve noticed that the performance of these tools can vary significantly depending on the weather, and I’m not alone in this observation.

I’ve reached out to other professionals in the field, collecting their experiences and tips for using impact driver drills in cold weather. From construction workers in the frosty north to repair technicians who have to brave the winter chill, these stories and case studies offer a wealth of practical knowledge.

Stay tuned as we delve into these real-life experiences, sharing the challenges faced and the solutions discovered. These firsthand accounts will not only help you understand the intricacies of using impact driver drills in cold weather but also equip you with the knowledge to overcome these challenges.

Remember, we’re in this together, and through sharing our experiences, we can all become more proficient and efficient, no matter the weather conditions we face.

My Personal Maintenance Tips for Impact Driver Drills in Cold Weather

In this section, I want to delve deeper into the maintenance aspect of using impact driver drills in cold weather. While I’ve previously touched on some preventive measures, I believe it’s crucial to provide a more comprehensive guide on how to care for your tool during the colder months.

From my experience, maintaining your impact driver drill in cold weather goes beyond just preventive measures. It involves a routine of cleaning, proper storage, and regular checks to ensure your tool is always in optimal working condition.

Cleaning your impact driver drill is an essential first step. Cold weather can cause a buildup of moisture and ice, which can affect the tool’s performance. I make it a point to clean my drill after each use, ensuring that all parts are dry and free of debris.

Storage is another critical aspect of maintenance. I’ve found that storing my impact driver drill in a warm, dry place significantly improves its performance in cold weather. This helps to prevent the battery and motor from being exposed to extreme cold, which can lead to reduced power output and even complete battery failure.

Lastly, routine checks are a must. Before each use, I inspect my drill for any signs of wear and tear, especially on the cords and connections. Cold weather can make these parts more brittle and prone to cracking, which can cause the tool to malfunction.

By following these maintenance tips, I’ve been able to ensure that my impact driver drill is always ready to perform, even in the coldest of weather conditions. I hope that by sharing these tips, you too can keep your tool in top shape throughout the winter months.

Suggested Reading: Do I Need An Impact Driver

My Safety Tips for Using Impact Driver Drills in Cold Weather

In this section, I want to focus on an aspect that is often overlooked but is of utmost importance – safety. Using power tools, such as impact driver drills, in extreme weather conditions can indeed pose certain risks. From my experience, I’ve gathered some safety tips that I follow when using my impact driver drill in cold weather, and I believe sharing these could be of great value to you.

Firstly, it’s crucial to dress appropriately for the cold weather. This doesn’t just mean bundling up to stay warm, but also ensuring that your clothing doesn’t interfere with the operation of your tool. I always make sure to wear gloves that provide both warmth and dexterity, allowing me to handle my drill safely.

Secondly, I’ve found that taking regular breaks to warm up can help prevent numbness in the hands, which could lead to a loss of control over the tool. I make it a point to step indoors or into a heated vehicle for a few minutes every hour.

Another safety tip I follow is to keep my work area well-lit. Cold weather often comes with shorter daylight hours, and working in low light conditions can increase the risk of accidents. I always ensure that I have adequate lighting, whether it’s natural daylight or a reliable artificial light source.

Lastly, it’s important to remember that cold weather can affect the performance of your impact driver drill. I always start slowly, giving both myself and the tool time to adjust to the cold conditions. This helps me maintain control over the drill and reduces the risk of sudden malfunctions.

By following these safety tips, I’ve been able to use my impact driver drill in cold weather without compromising on safety. I hope that by sharing these, you too can ensure a safe and productive work environment, no matter how cold it gets.

FAQs: Why Impact Driver Drill Don’t Work In Cold Weather

Impact driver drills are an essential tool for DIY enthusiasts and professionals alike, but they may not work as expected in cold weather. If you’ve ever experienced your impact driver drill failing to start or not delivering the same amount of torque in cold weather, you’re not alone. In this FAQ section, we’ll explore why impact driver drills don’t work in cold weather and what you can do to prevent it from happening.

1: Why do impact driver drills struggle in cold weather?

Impact driver drills are powered by batteries, and batteries perform differently in cold temperatures. When the temperature drops, the chemical reaction in the battery slows down, which reduces the battery’s overall capacity and output. This leads to a decrease in the performance of your impact driver drill, and it may not work at all in extreme cold temperatures.

2: Can I still use my impact driver drill in cold weather?

Yes, you can still use your impact driver drill in cold weather, but you need to take a few precautions. First, keep your batteries warm by storing them in a warm place, such as inside your home or a heated garage. Second, consider using batteries with a higher capacity or amperage rating, as they tend to perform better in cold weather. Finally, give your batteries time to warm up before using them in your impact driver drill.

3: Is there any way to prevent impact driver drills from failing in cold weather?

Yes, there are a few ways to prevent impact driver drills from failing in cold weather. First, try to keep your impact driver drill and batteries at a consistent temperature by storing them in a warm place. Second, invest in batteries with a higher capacity or amperage rating, as they tend to perform better in cold weather. Finally, consider using a battery-powered impact driver drill that uses brushless motors, as they tend to be more efficient and require less energy, which can help extend battery life in cold weather.

Further Reading: Best Impact Driver Drill Under $40.

Conclusion

Cold weather can have a significant impact on the performance of your impact driver drill. By taking preventive measures and using troubleshooting tips, you can ensure that your tool performs optimally in cold weather conditions. Remember to store your drill in a warm location, use a lithium-ion battery, and keep the moving parts lubricated. With these tips, you can ensure that your impact driver drill is always ready to get the job done, even in the coldest of weather conditions.