How Does an Impact Driver Drill Work? A Comprehensive Guide

Why Impact Driver Drill Work?

An impact driver operates by applying a rotational motion along with sudden, intense force and elevated torque to insert fasteners. This rotation follows a pattern of advancing two steps and then retreating one step, with the impact occurring as frequently as 50 times a second whenever the driver meets with resistance.

Impact driver drills have become an essential part of my toolkit, and I’m sure many other DIY enthusiasts would agree. These powerful tools offer unmatched efficiency when it comes to driving or removing fasteners, making them a go-to for a variety of projects.

So, are you ready to dive in? Let’s embark on this journey of discovery together, exploring the fascinating world of impact driver drills. Whether you’re a seasoned DIY veteran or a curious beginner, there’s always something new to learn. Let’s get started!

Impact Driver Drill Basics

Definition and main components

An impact driver drill is a power tool designed to drive screws and other fasteners with high torque and speed, thanks to its unique combination of components:

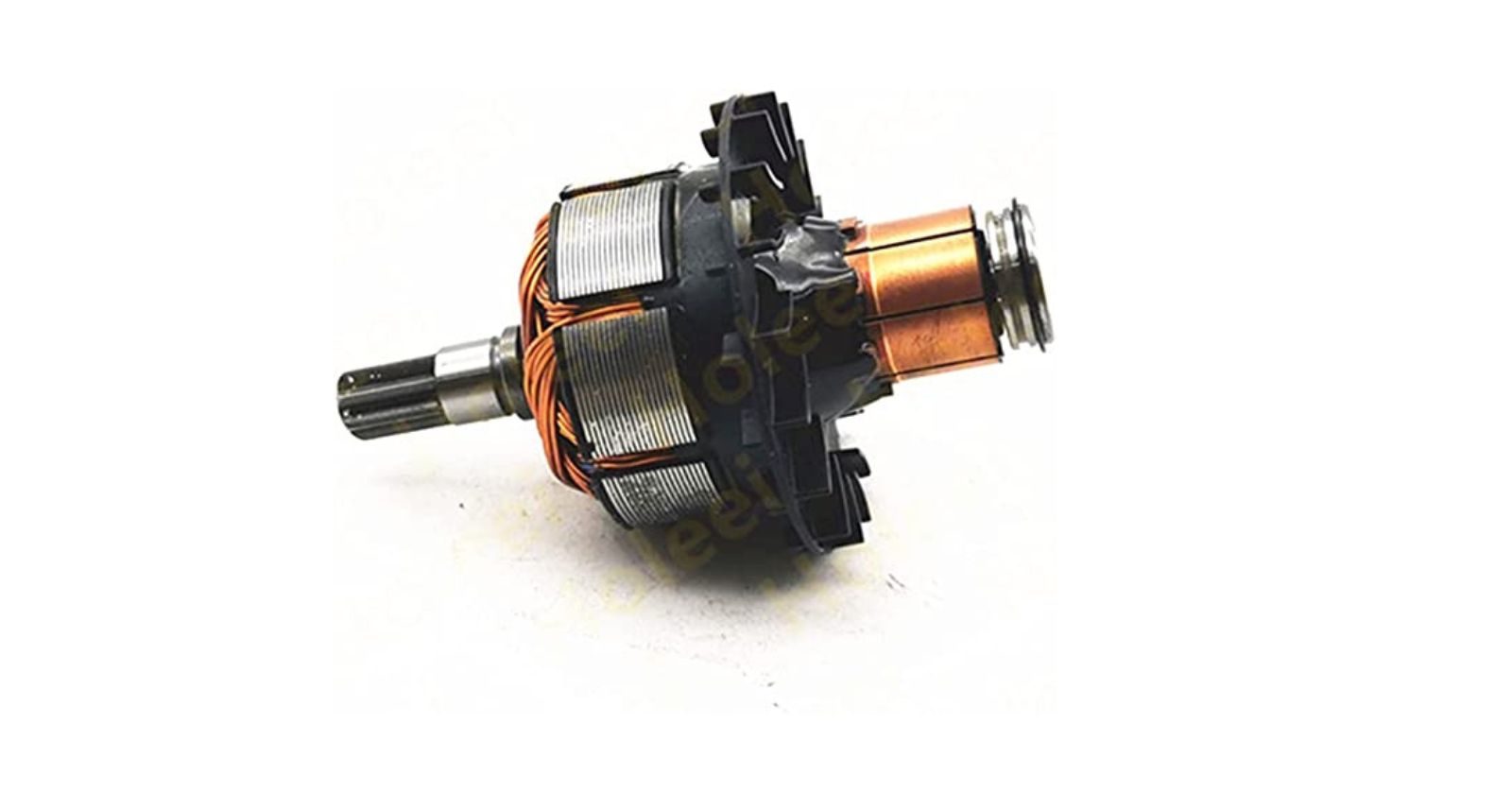

Motor:

The heart of the tool, converting electrical energy into mechanical energy to generate rotational force.

Chuck:

Holds the bit securely in place, ensuring proper transfer of power and torque.

Gear system:

Reduces the motor speed and increases the torque to drive fasteners effectively.

Hammer mechanism:

Delivers bursts of rotational force, providing the “impact” that distinguishes these tools from traditional drills.

Battery or power source:

Supplies the necessary energy to the motor, with options including corded and cordless models.

Comparison to traditional drills

Impact driver drills differ from traditional drills in several key ways:

Key differences:

While both tools use rotation to drive fasteners, impact drivers incorporate a hammer mechanism that delivers high torque and concussive force, making them more efficient for driving large or stubborn fasteners.

Unique benefits of impact drivers

They’re compact, lightweight, and produce less wrist strain due to their high-torque capabilities.

Most impact driver drills have variable speed triggers, allowing users to control the rotation speed and torque by modulating the flow of electricity.

The Mechanics of an Impact Driver Drill

How the motor generates power

Electricity and magnets:

The motor relies on electromagnetism, with current flowing through coils to create magnetic fields that push and pull the motor’s rotor, generating rotation.

Rotation speed and torque control:

Gearing system and its role

Speed reduction:

The gearing system reduces the motor’s high rotation speed, making it more suitable for driving fasteners.

Increased torque:

As the speed decreases, the torque increases, allowing the tool to deliver enough force to drive even the toughest fasteners.

Hammer mechanism and impact force

How it works:

When the tool encounters resistance (e.g., a tight fastener), the hammer mechanism engages, delivering short, powerful bursts of rotational force to overcome the resistance.

Role in driving and loosening fasteners:

The hammering action enables the impact driver drill‘ to drive or remove fasteners quickly and efficiently, with less effort and strain on the user.

Power sources and their impact on performance

Corded vs. cordless:

Corded models offer consistent power but limit mobility, while cordless versions provide portability but may suffer from reduced power as the battery depletes.

Battery types and capacity:

Lithium-ion batteries are the most common choice for cordless impact driver drills, offering long runtime, lightweight design, and minimal self-discharge.

Advantages and disadvantages:

Choosing between corded and cordless models depends on your specific needs, such as job site access to power outlets or the importance of tool mobility.

Proper Use of an Impact Driver Drill

Selecting the right bit

Types of bits:

Impact driver drills use 1/4-inch hex shank bits, available in various styles to match different fastener types.

Importance of matching the bit with the fastener:

Using the correct bit ensures efficient power transfer, reduces the risk of damaging the fastener or bit, and provides a secure fit to prevent slipping.

Setting up the tool

Inserting and securing the bit:

To insert the bit, pull the chuck collar forward, insert the bit until it clicks into place, and release the collar to secure it.

Adjusting speed and torque settings:

Some impact driver drills have adjustable speed and torque settings, allowing you to tailor the tool’s performance to your specific task. Consult your tool’s manual for instructions on making these adjustments.

Using the impact driver drill safely

Protective gear:

Always wear safety goggles, ear protection, and gloves when operating an impact driver drill to protect yourself from debris, noise, and vibration.

Proper handling techniques:

Hold the tool firmly with both hands, using the auxiliary handle if provided, to maintain control and reduce strain on your wrists and arms.

Awareness of surroundings and potential hazards:

Keep your work area clean and free of obstacles, be mindful of others nearby, and avoid using the tool in wet or damp conditions to reduce the risk of injury or damage.

Regular cleaning and inspection

External surfaces:

Wipe down the tool’s exterior with a clean, dry cloth after each use to remove dust and debris.

Motor and internal components:

Periodically inspect the motor brushes, gears, and other internal parts for wear or damage, replacing them as needed.

Proper storage and transportation

Carrying cases and storage solutions

Store your impact driver drill in a protective case or tool bag to shield it from damage during transport or storage.

Protecting the tool from environmental factors:

Keep the tool in a cool, dry place away from moisture, heat, and direct sunlight to prevent rust, corrosion, and damage to internal components.

Battery care and maintenance

Charging best practices:

Charge batteries fully before using them, and avoid overcharging or deep discharging to extend battery life.

Maximizing battery life:

Store batteries in a cool, dry location, and remove them from the charger once fully charged to prevent overcharging.

FAQs: How Does an Impact Driver Drill Work? A Comprehensive Guide

I invite you to explore the wealth of resources available on impactdriverdrill.com for more tips, product reviews, and troubleshooting advice. From mastering the basics to tackling advanced techniques, our goal is to help you get the most out of your impact driver drill and become a true power tool pro. Happy drilling! An impact driver drill is a powerful tool that is commonly used in construction and DIY projects. It is designed to drive screws and bolts quickly and efficiently, making it an essential tool in any workshop or job site. In this guide, I will explain how an impact driver drill works and answer some of the most frequently asked questions about this versatile tool.

How does an impact driver drill work

An impact driver drill works by using concussive force to drive screws and bolts into various materials. Inside the tool, there is a motor that rotates a spring-loaded hammer, which then strikes the back of the driver bit. This action creates a high-torque rotational force that enables the driver bit to easily drive screws and bolts into tough material

What makes an impact driver drill different from a regular drill?

An impact driver drill is different from a regular drill because it uses concussive force to drive screws and bolts, while a regular drill relies solely on rotational force. The concussive force of an impact driver drill makes it easier to drive screws and bolts into hard materials, which would be difficult or impossible with a regular drill.

Can an impact driver drill be used for other tasks besides driving screws and bolts?

Yes, an impact driver drill can be used for other tasks besides driving screws and bolts. With the right attachments, an impact driver drill can be used for drilling holes, sanding, and even polishing. However, it is important to note that while an impact driver drill is versatile, it is still primarily designed for driving screws and bolts.

The Final Bit

Understanding the inner workings of an impact driver drill will help you use the tool more efficiently and safely, ensuring that you get the most out of this powerful and versatile power tool. Now that you’re equipped with this knowledge, you’re ready to tackle your next project with confidence and skill. Whether you’re a DIY enthusiast or a seasoned professional, an impact driver drill can make your work easier, faster, and more enjoyable.

More Troubleshooting Posts:

Here are some additional guides and content about troubleshooting: