How To Use An Angle Grinder On Concrete

Now, let’s talk about how to use an angle grinder on concrete. Concrete is the backbone of countless construction and home projects, but working with it is no walk in the park. It’s hard, relentless, and shows no mercy. While I’ve seen many tools buckle under its stern nature, the angle grinder has always been my trusty companion when it comes to using an angle grinder on concrete.

Armed with the right disc and technique, I’ve carved through concrete blocks, smoothed out those pesky rough patches, and even crafted detailed designs. The key to using an angle grinder on concrete effectively is not just about raw power; it’s about the art of it.

With an angle grinder in my grip and the right knowledge, I’ve managed to produce work that’s not only efficient but also pleasing to the eye. Learning how to use an angle grinder on concrete is a valuable skill that can make your projects more efficient and aesthetically pleasing.

What is an Angle Grinder?

Basics of Angle Grinders

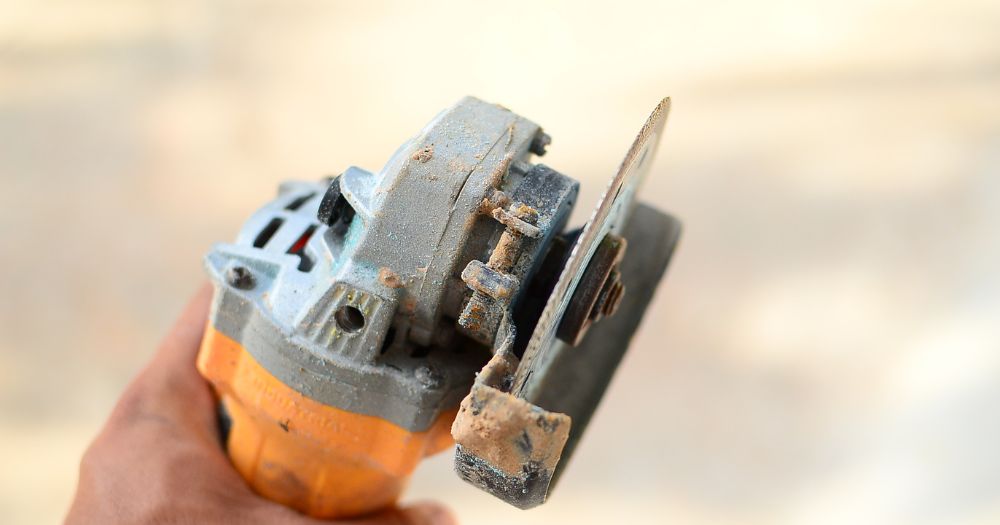

The first time I laid my hands on an angle grinder, I’ll admit, I underestimated it. It seemed straightforward, almost basic. But the more I experimented with it, the more I came to appreciate its raw power packed in such a compact frame. Most people might know it simply as a ‘grinder’, but for me, it’s a jack-of-all-trades. Whether it’s grinding, cutting, or polishing, this tool has got it covered.

At its core, it’s driven by an abrasive disc, whirling away at incredible speeds, all thanks to its electric or pneumatic motor. And the design? It’s ergonomic, complete with a protective guard, ensuring that every time I use it, I’m both safe and comfortable. No wonder it’s become a mainstay in my workshop.

When it comes to the types of angle grinders, here’s my take:

- Electric Angle Grinders: These are my trusty sidekicks for most heavy-duty tasks. They’re powered directly from an electrical outlet, and boy, do they deliver! The only catch? Being mindful of that power cord.

- Cordless Angle Grinders: Whenever I need to move around freely, these are my go-to. Powered by batteries, they might not always match the sheer force of the corded ones, but the freedom they grant is worth it.

- Pneumatic Angle Grinders: These are air-driven and are surprisingly light. Ideal for spots where electricity might be a concern, like when I’m working in damp conditions.

- Variable Speed Angle Grinders: These are a dream come true for any craftsman. The ability to adjust the speed means I can switch between delicate polishing tasks and aggressive grinding seamlessly.

Why Use an Angle Grinder on Concrete?

Ah, concrete. The ever-present behemoth in construction. It’s sturdy and reliable, but when it comes to making modifications, it can be a real challenge. That’s where my angle grinder shines.

- Speed and Efficiency: In my line of work, every minute counts. Thanks to the powerful motors and the rapid rotations of the disc, my angle grinder breezes through concrete tasks. Whether I’m carving out a space for a new door or leveling an uneven edge, the speed and efficiency are unparalleled.

- Precision: What I love about my angle grinder is that it’s not just about brute force. It’s a tool of finesse. Need to carve a slim channel in concrete for some piping? Or maybe get that floor just perfectly level? With a firm grip and the right disc, the precision I can achieve is something other tools can only dream of.

And the versatility? It’s astounding. Beyond just cutting and grinding, with the right attachments, I’ve used my angle grinder for everything from stripping away old paint and rust to crafting intricate designs on concrete surfaces. It’s this combination of strength, precision, and adaptability that convinces me, time and again, of the angle grinder’s indispensable role when working with concrete.

Safety First: Preparing to Use an Angle Grinder on Concrete

Whenever I’m about to tackle a project involving power tools and tough materials like concrete, I always remind myself: safety isn’t just a good idea—it’s an absolute must. My angle grinder, despite its compact size, is a beast. It’s powerful, versatile, and demands my most respect and caution. So, before I dive in, I always run through my safety checklist to ensure I’m not only doing the job right but also doing it safely.

Essential Safety Gear

Gearing up to use my angle grinder always feels like a ritual. It’s akin to a pilot preparing for takeoff. Each piece of safety gear has its unique role, and missing even one can spell trouble.

- Safety goggles: These are my first line of defense. With concrete particles that can shoot off unpredictably, these goggles are my eyes’ best friends. I personally vouch for the anti-fog and scratch-resistant varieties—they offer a clear, unobstructed view, ensuring precision in my work.

- Dust mask or respirator: I’ve learned the hard way that concrete dust isn’t something to take lightly. Over time, it can wreak havoc on the respiratory system. So, I never start without ensuring my mask or respirator fits just right, filtering out those harmful micro-particles.

- Ear protection: The shrill sound of the grinder working against concrete is not just annoying—it’s potentially harmful. I’ve made it a habit to always use earplugs or earmuffs. They help keep the noise at bay and my ears safe.

- Gloves: These aren’t just about protection from sparks or rough concrete edges. A good pair of gloves gives me a firmer grip on my grinder, reducing any chances of slips or mishaps. I always ensure they’re durable yet flexible enough for me to maneuver easily.

Setting Up Your Workspace

The space I work in is as vital as the gear I wear. Setting it up correctly is half the battle won. Here’s how I prep my workspace:

- Well-ventilated area: Concrete dust is sneaky. It can cloud up a space in no time, reducing visibility and posing health risks. I always choose a spot with ample airflow—it keeps the dust in check and offers a clearer view of my work.

- Remove flammable materials: Those tiny sparks from the grinder? They can be more dangerous than they look. I always take a moment to clear my workspace of anything that can catch fire—be it rags, papers, or certain chemicals.

- Wet the concrete: This is one of those insider tips I picked up along the way. A slightly dampened concrete surface not only produces less dust but also keeps the grinder’s blade cooler, ensuring smoother operation.

- Stable working surface: There’s nothing more frustrating (and risky) than a wobbly workpiece. Before I start, I make sure the concrete I’m working on is stable. If it’s a smaller, movable piece, clamps or braces become my best allies.

Safety, in my book, isn’t a one-off thing—it’s a continuous journey. Being aware of my surroundings, routinely checking my tools and gear, and taking my time are principles I swear by. With a methodical, safety-first mindset, I’ve found that every project not only ends successfully but also safely.

Watch This Video And Learn How To Use An Angle Grinder On Concrete

Step-by-Step Guide: How I Use An Angle Grinder On Concrete

When I first tried my hand at using an angle grinder on concrete, I’ll admit, it felt like a daunting task. But with the right techniques and a bit of patience, I’ve come to not only master it but also enjoy the process. Let me walk you through my approach.

Choosing the Right Disc

To me, the disc for a grinder is like a brush for a painter—it’s essential.

- Diamond blades: Every time I need to cut concrete, I instinctively reach for my diamond blades. Their unmatched durability and sharpness guarantee a clean, efficient cut. They might set you back a bit more than regular blades, but believe me, the precision and speed they bring to the table are worth every penny.

- Silicon carbide discs: When I’m looking to refurbish a concrete surface or smooth out some rough spots, silicon carbide discs become my best friends. Their abrasive quality ensures the surface gets the perfect treatment without any excessive damage.

Setting the Correct Speed

It’s a bit like driving—knowing when to speed up and when to cruise is crucial.

- Importance of adjustable speed settings: Different projects require different speeds. Having an adjustable speed setting on my grinder is like having a Swiss army knife. It lets me tweak the speed to perfectly match the task, ensuring top-notch results every time.

- Recommended speeds for concrete: Through trial and error, I’ve discerned that a medium to high speed usually does the trick for most concrete tasks. However, a pro tip: always start slow and gradually increase the speed. It’s not just safer but also helps you get a feel for the material.

The Grinding Process

This is where the rubber meets the road, or in this case, the disc meets the concrete.

- Holding the grinder at the right angle: Laying the grinder flat on the surface isn’t the way to go. I’ve found that a slight angle, somewhere between 15-30 degrees, is the sweet spot. It ensures efficient grinding and minimizes the risk of the disc catching on the concrete.

- Applying consistent pressure: It’s all about finding that balance. Push too hard, and you’ll wear out the disc or, worse, damage the concrete. Too gentle, and you might as well not do anything. Over the years, I’ve honed my technique to apply just the right amount of pressure.

- Moving steadily and controlled: Speed isn’t the goal here. Rushed, erratic movements can ruin the finish. I always make it a point to move the grinder in a controlled, steady fashion, ensuring uniform contact with the concrete.

Tips for a Smooth Finish

It’s the little things that count.

- Wet grinding vs. dry grinding: I’ve noticed that wet grinding, with its cooling effect, often yields a superior finish. But it can get messy. So, for indoor tasks or when I’m not in the mood to deal with the slush, I go for dry grinding. However, I always have dust control measures in place.

- Using a dust shroud: This tool has been a game-changer for me. Particularly during dry grinding sessions, a dust shroud effectively contains the concrete dust, ensuring I have a neat workspace and an unobstructed view of my project.

- Regularly checking the disc for wear: It’s akin to checking the soles on your favorite pair of running shoes. An overly worn-out disc can hamper efficiency and affect the quality of the finish. I always keep an eye on my disc’s condition and replace it when necessary.

Over time, I’ve come to realize that mastering the angle grinder on concrete is a mix of knowledge, technique, and hands-on experience. With every project, I feel more adept and more confident. And one golden rule I always abide by: in the realm of power tools, safety and patience are paramount. I hope my insights help you on your grinding journey!

Cleaning and Maintenance

Over the years, I’ve come to realize that the secret to a tool’s longevity and peak performance lies in the care it receives after the work is done. An angle grinder, with its robust capabilities, is no exception. Here’s a more in-depth look into the cleaning and maintenance rituals I swear by.

Post-Grinding Cleanup

The aftermath of a grinding session can be messy. But with a systematic approach, cleanup becomes a breeze.

- Cleaning the grinder:

- Unplugging: The first thing I do, without fail, is unplug the grinder. Safety always comes first.

- Exterior cleaning: Using a soft brush or cloth, I gently brush away the concrete dust and particles from the tool’s body. It’s surprising how much dust can accumulate after just one session.

- Vents and crevices: These areas can be a bit tricky. Compressed air is my go-to solution. A few short bursts, and the vents are as good as new. Keeping these clear is essential; a clogged vent can lead to the motor overheating.

- Blade inspection: After every use, I inspect the blade for any signs of wear or damage. A compromised blade can affect performance and safety.

- Properly disposing of concrete dust:

- Gathering the dust: I use a shop vacuum with a fine dust filter to collect the concrete dust. It’s efficient and ensures minimal dust escapes into the air.

- Safe disposal: Once collected, I transfer the dust to a heavy-duty bag, seal it securely, and label it. It’s essential to be aware of local disposal regulations. Some municipalities have specific guidelines for construction-related waste to ensure environmental safety.

Maintaining Your Angle Grinder

Routine maintenance is the cornerstone of a tool’s longevity and optimal performance.

- Regular inspections:

- Power cord check: Before I even plug in my grinder, I inspect the power cord. Any nicks, cuts, or exposed wires are a red flag. A compromised cord can be a potential electrical hazard.

- Disc security: I ensure the disc is securely attached and doesn’t wobble. An unstable disc can lead to uneven grinding or, worse, accidents.

- Visual inspection: A quick look over the grinder can reveal potential issues like cracks, loose parts, or other visible damages.

- Replacing worn-out parts:

- Brushes: The brushes inside the grinder wear out over time, especially with frequent use. If I notice a drop in performance or the grinder struggling, the brushes are often the culprits. Replacing them is usually straightforward, and it can breathe new life into the tool.

- Bearings: A squeaky or rattling grinder often points to worn-out bearings. Regular lubrication can extend their life, but once they’re past their prime, replacement is the best option.

- Discs: This is a no-brainer. A worn-out or damaged disc can compromise both safety and efficiency. I always have a set of replacement discs on hand, ensuring I can swap them out when needed.

In essence, the key to a long-lasting and efficient angle grinder is a mix of regular cleaning, timely maintenance, and a keen eye for detail. By treating your grinder with the care it deserves, it’ll serve you reliably for years to come. I hope this expanded section offers the depth and detail you’re seeking!

FAQs

Before diving into the specifics, it’s important to note that working with concrete is both an art and a science. While the angle grinder is a powerful tool in this endeavor, knowing how to use it effectively is key. Here are some frequently asked questions that can help you get the most out of your angle grinder when working with concrete.

What type of disc should I use for cutting concrete?

For cutting concrete, a diamond-tipped disc is generally the best choice. These discs are specifically designed to handle the hardness of concrete and provide a clean, efficient cut. Make sure to choose a disc that is appropriate for the thickness and type of concrete you are working with.

How do I safely operate an angle grinder when working with concrete?

Safety should be your top priority when using an angle grinder on concrete. Always wear appropriate personal protective equipment, including safety goggles, gloves, and ear protection. Make sure the grinder has a handle for two-handed operation and that you are standing in a stable position. Always turn off the grinder and unplug it when changing discs.

Can I use an angle grinder for detailed concrete work?

Yes, angle grinders can be used for more detailed work on concrete, such as crafting designs or smoothing out smaller rough patches. However, this requires a steady hand and specialized discs like grinding or polishing pads. It’s advisable to practice on a scrap piece of concrete to get the hang of it before working on your main project.

To Wrap Things Up With How To Use An Angle Grinder On Concrete

As we draw the curtain on this in-depth exploration of using an angle grinder on concrete, it’s essential to pause and reflect on the journey we’ve embarked upon together.

The world of power tools is vast and varied, but few tools hold the transformative power that an angle grinder does. Its ability to reshape, refine, and redefine concrete is nothing short of remarkable. But, as I’ve learned through countless hours of hands-on experience, this power is a double-edged sword. While it can create wonders, it demands respect, understanding, and a commitment to safety.

The importance of using an angle grinder safely cannot be overstated. Every disc choice, every speed setting, and every movement is a testament to the balance between safety and efficiency. It’s this balance that ensures not only the longevity of your tool but also the quality of your work and, most importantly, your well-being.

But beyond the technicalities and safety protocols lies a deeper truth: mastery is a journey, not a destination. Each time you grip that grinder, each spark that flies, and each line you etch on the concrete is a step forward in this journey. Mistakes, setbacks, and challenges are all part and parcel of the learning curve. Embrace them. They’re not just obstacles; they’re lessons in disguise.

I’ve always believed that the heart of craftsmanship lies in the continuous pursuit of perfection. And while perfection might seem elusive, the pursuit is where the magic happens. With every project, you’ll discover nuances, develop techniques, and gain insights that textbooks and guides can’t teach. It’s this hands-on experience, combined with knowledge, that shapes a novice into a master.

So, to everyone eager to harness the power of the angle grinder, I say this: Dive in with passion, arm yourself with knowledge, and respect the craft. The road to mastery is paved with practice, patience, and persistence. And as you journey on, you’ll find that the angle grinder isn’t just a tool; it’s an extension of your creativity, turning your vision into tangible reality.

In the grand tapestry of craftsmanship, every stroke, cut, and grind you make with your angle grinder adds a unique thread. So, wear your safety gear, power up that grinder, and etch your legacy on the canvas of concrete. The world awaits your creations.

More Grinder Resources:

Before you go off and grind something with your new found information have a look at other (Easy) Grinder guides below

- Top 5 Best Grinder For Sharpening Lathe Tools Of 2023

- Top 5 Best Slow Speed Bench Grinders for Sharpening: A Beginner’s Guide for 2023

- The 5 Best Wood Lathe Tool Sharpening System Of 2023