The 5 Best Grinder Jigs For Wood Lathe In 2024

In my journey through craftsmanship, I’ve come to realize that precision and attention to detail are everything. The tools I use aren’t just tools; they’re The 5 Best Handheld Angle Grinders For Concrete In 2024 of my skills and intentions. Among all the tools in my arsenal, grinder jigs, often overlooked, have been game-changers. So, what is it about grinder jigs that makes them so indispensable in the world of lathes?

At its essence, a grinder jig is like a trusted companion for your tools. It’s designed to hold another tool at just the right angle, ensuring consistent and precise sharpening. Think about it: have you ever tried to sharpen a pencil without a sharpener, using just your hands and some sandpaper?

The result is usually uneven and far from ideal. It’s the same with lathes. In a domain where precision is paramount, grinder jigs are that perfect sharpener, ensuring every tool I use is honed to perfection.

When I work with lathes, their spinning action shapes materials by rotating them against a cutting tool. The sharpness of this cutting tool can be the difference between creating a masterpiece and ending up with a piece of scrap.

That’s where the best grinder jig for wood lathe comes into play. By ensuring my tools are always sharp, at the right angle, and free from imperfections, grinder jigs have elevated the quality of my work.

But it’s not just about sharpness. Grinder jigs have been a lifesaver in terms of safety. A sharp tool requires less force, reducing the chances of any unfortunate accidents. Plus, by minimizing wear and tear on my tools, I’ve come to see grinder jigs as an investment, prolonging the life of my cherished equipment.

As I dive deeper into this Top 5 Best Grinder Jig For Wood Lathe In 2023 guide, I’ll share more about the nuances of grinder jigs, from their rich history to the latest innovations that make them indispensable

. Whether you’re a seasoned pro, a passionate hobbyist, or just dipping your toes into the world of lathes, I believe that understanding the value and functionality of the best grinder jig for wood lathe will truly elevate your craft.

The 5 Best Grinder Jigs For Wood Lathe In 2024(Updated List)

| # | Preview Images | Products | Rating |

|---|---|---|---|

| 1 |  | Tormek SVD-186 Turning Tool Sharpener | 5.0 |

| 2 |  | JET 727200 Wood Turning Jig Set | 4.5 |

| 3 |  | Woodcut Tools Tru-Grind Jig Turning Tool | 4,0 |

| 4 |  | Wolverine Grinding System with VARI-GRIND Jig | 3.5 |

| 5 |  | Pro Grind Multi-Grind Sharpening Jig | 3.0 |

The Evolution of Grinder Jigs

My journey with grinder jigs has been nothing short of fascinating. It’s a tale deeply intertwined with the broader story of human innovation and our collective pursuit of craftsmanship perfection.

The Humble Beginnings

Before I even knew the term “grinder jig,” I was captivated by the tales of ancient civilizations and their reverence for sharp tools. From the ingenious methods of the early Egyptians to the craftsmanship of the Romans, the art of sharpening was just that—an art. They used stones of different grits to achieve those sharp edges. While the idea of a ‘jig’ to aid this process was still a distant concept, the foundational principles of maintaining consistent tool angles were already being practiced.

The Birth of the Jig Concept

As I dive deeper into history, I realized that as societies evolved and industrial demands surged, the art of sharpening transformed into a science. The Middle Ages marked the dawn of jigs—rudimentary wooden or metal aids that ensured a consistent sharpening angle against grinding wheels or stones. I’ve heard tales of blacksmiths and craftsmen of yore, creating their own jigs and passing down their designs like cherished heirlooms.

The Industrial Revolution and Standardization

The industrial revolution reshaped my understanding of many tools, and grinder jigs stood out prominently. The era of mass production ushered in a dire need for standardized tools and uniform sharpening techniques. Metal, with its durability and resilience, became the go-to material for jigs, phasing out the earlier wooden designs. These jigs weren’t just sturdier; they were also more versatile, with adjustable components catering to a myriad of tools.

The 20th Century: A Century of Rapid Advancements

The 20th century was a whirlwind of technological marvels. I witnessed materials science introducing elements like hardened steel, alloys, and ceramics to the grinder jig realm. These weren’t just incremental upgrades; they transformed the longevity and precision of the jigs.

Then came computer-aided design (CAD), a revolution in true sense. Suddenly, jigs could be custom-made for specific tools and tasks with an accuracy that was once deemed unattainable. And as the century progressed, digital components made their way into the mix, with advanced jigs boasting digital angle finders and laser guides.

The Modern Era: Automation and Beyond

Now, as I navigate the modern landscape, I see grinder jigs standing tall at the pinnacle of technological innovation. Automated grinding systems, complete with integrated jigs, promise sharpening with minimal human touch. These marvels, equipped with sensors and driven by AI algorithms, guarantee impeccable sharpening angles and pressure.

And with the advent of 3D printing, the game has changed altogether. Fellow craftsmen and I can now design and print custom jigs right in our workshops, allowing for on-the-fly modifications and tweaks.

Looking Ahead: The Future of Grinder Jigs

Peering into the horizon, I’m filled with anticipation and excitement for the future of grinder jigs. With breakthroughs in AI, cutting-edge materials science, and the tantalizing promise of quantum computing, I can’t help but wonder: Will the next-gen jigs be self-adjusting? Will they learn on the go? Might they even predict when my tool needs that perfect sharpening touch?

The evolution of grinder jigs is a testament to humanity’s relentless pursuit of perfection. From simple stones to AI-driven systems, this journey underscores our innate desire to improve, innovate, and excel.

Why Do I Need a Grinder Jig for My Lathe?

Working with lathes has taught me the importance of precision at every turn. The tools I use with my lathe have to be top-notch. That’s where grinder jigs come in, the unsung heroes in my workshop, ensuring my lathe tools are always at their peak performance. Let me share more about why I find these jigs indispensable.

Ensuring Precision and Accuracy

The Role of Grinder Jigs in Achieving Precise Cuts and Finishes:

Lathing isn’t just about skill; it’s very much about the tools. My grinder jig guarantees that my tool’s edge remains consistently sharp and at the right angle. This means smoother operations, fewer mistakes, and a finish that truly showcases my craftsmanship.

How Jigs Prevent Common Mistakes and Mishaps:

Even with years under my belt, I’ve had my share of slip-ups during manual sharpening. One small oversight, and I could end up with an uneven edge or a skewed angle. My grinder jig is like a trusted mentor, guiding my sharpening process and minimizing errors. It takes out the guesswork, leaving me with a tool that’s flawlessly honed and ready for action.

Extending Tool Life

The Importance of Sharp Tools for Lathes:

A sharp tool is an efficient tool. When it’s sharp, it interacts seamlessly with the material, eliminating the need for excessive force or multiple passes. This not only gives a superior finish but also reduces wear on the tool, meaning fewer replacements and repairs.

How Grinder Jigs Help in Maintaining Tool Sharpness and Longevity:

Every sharpening session takes a toll on the tool. Without my jig’s precision, I might inadvertently over-sharpen, reducing the tool’s lifespan. My grinder jig ensures I remove just the right amount of material, safeguarding the tool’s integrity and prolonging its life. It’s like having a personal protector for my tools, ensuring they’re always in their prime.

Enhancing Workflow Efficiency

How Grinder Jigs Speed Up the Sharpening Process:

In my workshop, time is gold. Traditional manual sharpening can eat up precious minutes, especially when I’m aiming for perfection. My grinder jig, with its meticulous design and precision, speeds up the sharpening process. Tasks that used to take me several minutes are now done in a fraction of the time.

The Role of Jigs in Ensuring Consistent Results Every Time:

I remember the frustration of perfectly sharpening one tool, only to struggle with the next. Grinder jigs have put an end to that inconsistency. Whether I’m honing a set of chisels or a range of tools, my jig ensures uniform results, streamlining my workflow and boosting efficiency.

In the intricate world of lathes, where precision is everything, grinder jigs aren’t just tools for me; they’re invaluable assets. They guarantee that every cut, every finish, and every project meets the highest standards of craftsmanship. From my personal experience, I can’t stress enough the transformative impact a reliable grinder jig has on my work.

Watch This Video And Learn How To Use A Grinder Jig For A Wood Lathe

Features I Consider When Choosing a Grinder Jig for My Lath

In my quest for precision and ensuring the longevity of my lathe tools, I’ve found that a grinder jig is non-negotiable. But with so many options out there, how do I pinpoint the right one for my needs? Let me walk you through the key features I always have on my checklist:

Material and Build Quality

Sturdy Materials Like Steel or Iron:

Throughout my journey in craftsmanship, I’ve come to understand that the heart of a dependable grinder jig lies in its material. Steel and iron, celebrated for their resilience, are my top picks. They stand up to the demands of frequent sharpening, ensuring the jig remains steadfast.

Craftsmanship and Durability:

It’s not just about what it’s made of; it’s about how it’s made. The craftsmanship behind a jig is crucial. A meticulously constructed jig, boasting flawless fittings and finishes, operates like a dream. It’s the difference between a jig that’s short-lived and one that’s a long-term companion in my workshop.

Adjustability and Flexibility

The Need for Customizable Angles and Positions:

Each tool in my arsenal has its nuances. Some need a distinct angle for that perfect edge, while others require a specific position. A grinder jig that offers adjustable features is a godsend, letting me customize the sharpening process for each tool.

A Versatile Jig for Various Tools:

The beauty of a versatile jig is its adaptability. Instead of juggling between different jigs for different tools, a multi-purpose jig has got me covered. Be it a chisel or a gouge, I know I’ve got the right setup at my fingertips.

Safety Features

Secure Clamping and Stability:

Safety is paramount in my book. A jig that provides a solid grip and remains stable during use is essential. It ensures the tool stays put, warding off any potential accidents from unforeseen movements.

Additional Safety Measures:

Over time, I’ve grown fond of jigs that come with added safety features. Protective guards shield me from any stray splinters or sparks, and non-slip bases make sure the jig stays put, even on the slickest of surfaces.

Ease of Maintenance

Cleaning and Upkeep of My Grinder Jig:

Like all my tools, my grinder jig needs its share of TLC. Post every sharpening session, I ensure to clear off any lingering debris. For those tricky spots, a quick burst of compressed air works wonders. And a dab of lubricant on moving parts keeps things running smoothly.

The Value of Regular Maintenance:

The performance of a grinder jig is directly tied to its maintenance. Regular upkeep not only extends its life but also ensures it’s always performing at its best. A bit of time and care, and in return, I get tools that are consistently sharp.

In the vast world of craftsmanship, a grinder jig might appear as just another tool. But its influence is undeniable. By guaranteeing my tools are always at their peak, it uplifts the caliber of my work. So, if you’re setting out to pick a grinder jig for your lathe, remember these features. They’ve served me well, and I’m confident they’ll guide you to the perfect choice.

Top Picks: Best Grinder Jig For Lathes

Choosing the right grinder jig for your lathe can be a game-changer. After extensive research and hands-on testing, I’ve narrowed down my top three picks that stand out in the market. Here’s a closer look at each:

1. Tormek SVD-186 Turning Tool Sharpener

The Tormek SVD-186 R Gouge Jig has become an indispensable part of my sharpening toolkit. Seamlessly integrated with Tormek’s T8 system, this jig empowers me to replicate my chosen tool profiles with pinpoint accuracy.

What I love is how it minimizes steel removal, making touch-ups incredibly efficient. Its versatility is another highlight; it accommodates various bevel lengths and even allows for custom profile settings. The special shaft that comes with it is a game-changer for sharpening my turning cutters.

And let’s not forget the water-cooled grindstone—gentle enough to keep my most delicate tools from overheating. The newly added locking screw feature is the icing on the cake, simplifying the sharpening of specialized carving tools like never before.

Pros

- High-Level Control: Enables precise replication of tool profiles, ensuring consistent performance after each sharpening.

- Versatility: Suitable for sharpening a wide range of tools, from bowl and spindle gouges to turning cutters and specialized carving tools.

- Efficiency: Removes only a minimal amount of steel during the sharpening process, prolonging the life of your tools.

- Safety: The water-cooled grindstone is gentle on carbon steel, eliminating the risk of overheating.

Cons

- Learning Curve: May require some time to master the various settings and features.

- Price: The high level of precision and versatility may come at a premium cost.

2. JET 727200 Wood Turning Jig Set

I’ve got to say, this hand-powered sharpening system from JPW Industries is a game-changer for me. Weighing in at a mere 13.1 ounces and with compact dimensions of 10.39 x 6.54 x 2.36 inches, it’s a breeze to store and transport. The system is a jack-of-all-trades, featuring a Gouge Jig, Carving Tool Jig, and Chisel Angle Jig, all in one package. Its standard color effortlessly complements my workshop’s aesthetic. What seals the deal for me is its battery-free operation and the 90-day warranty, which adds an extra layer of peace of mind.

Pros

- Easy to Handle: Its lightweight design makes it incredibly portable and easy to store.

- All-in-One: The multiple jigs make it a versatile addition to my toolkit.

- Always Ready: The hand-powered mechanism means it’s always good to go, no batteries needed.

- Peace of Mind: A 90-day warranty gives me confidence in my purchase.

- Space-Saver: Its compact size is perfect for my already crowded workshop.

Cons

- Short Warranty: While I appreciate the 90-day warranty, a longer coverage period would be even better.

- Manual Operation: Being hand-powered is great for me, but some might miss the convenience of an electric system.

- Imported: It’s made in China, which could be a drawback for those who prefer domestic products.

3. Woodcut Tools Tru-Grind Jig Turning Tool

Elevate your woodworking experience with the Tru-Grind Jig, the all-in-one sharpening solution designed for ultimate precision and versatility. Compatible with a wide array of sharpening systems, including Woodcut Tools and Oneway, this jig is a must-have for any craftsman. What sets it apart is its ability to lock into place, ensuring an exact bevel angle every single time.

Just set the number once, and the jig will replicate your preferred bevel consistently, instilling confidence that your tools are always sharpened to perfection. But that’s not all; the Tru-Grind Jig is a true multitasker. Its tilting tool holder head accommodates a broad range of grinds and can handle tools up to 1-1/2″ in diameter, including

Bowl and Spindle gouges, Parting Tools, Skew chisels, and Spindle Roughing Gouges. Say goodbye to the clutter of multiple jigs; this is the only sharpening jig you’ll ever need. And with our 30-Day Money-Back Guarantee, you can try the Tru-Grind Jig risk-free. Experience the difference today!

Pros

- Universal Compatibility: Works seamlessly with most sharpening systems, offering great flexibility.

- Precision Sharpening: Locks into place for an exact bevel angle, ensuring consistent results.

- Multi-Tool Capability: One jig to sharpen a variety of tools, reducing the need for multiple jigs.

- High Capacity: Accommodates tools up to 1-1/2″ in diameter.

- Risk-Free Purchase: Backed by a 30-Day Money-Back Guarantee.

Cons

- Learning Curve: May take some time to get used to the settings for achieving the perfect bevel.

- Price: Could be on the higher end compared to basic jigs, but offers more features.

- Compatibility Exceptions: While it works with most systems, there may be some sharpening systems that are not fully compatible.

- Space Requirement: Given its versatility, it may take up more space than single-purpose jigs.

- Manual Setup: Requires manual setting of the bevel angle, which might not be ideal for those looking for automated solutions.

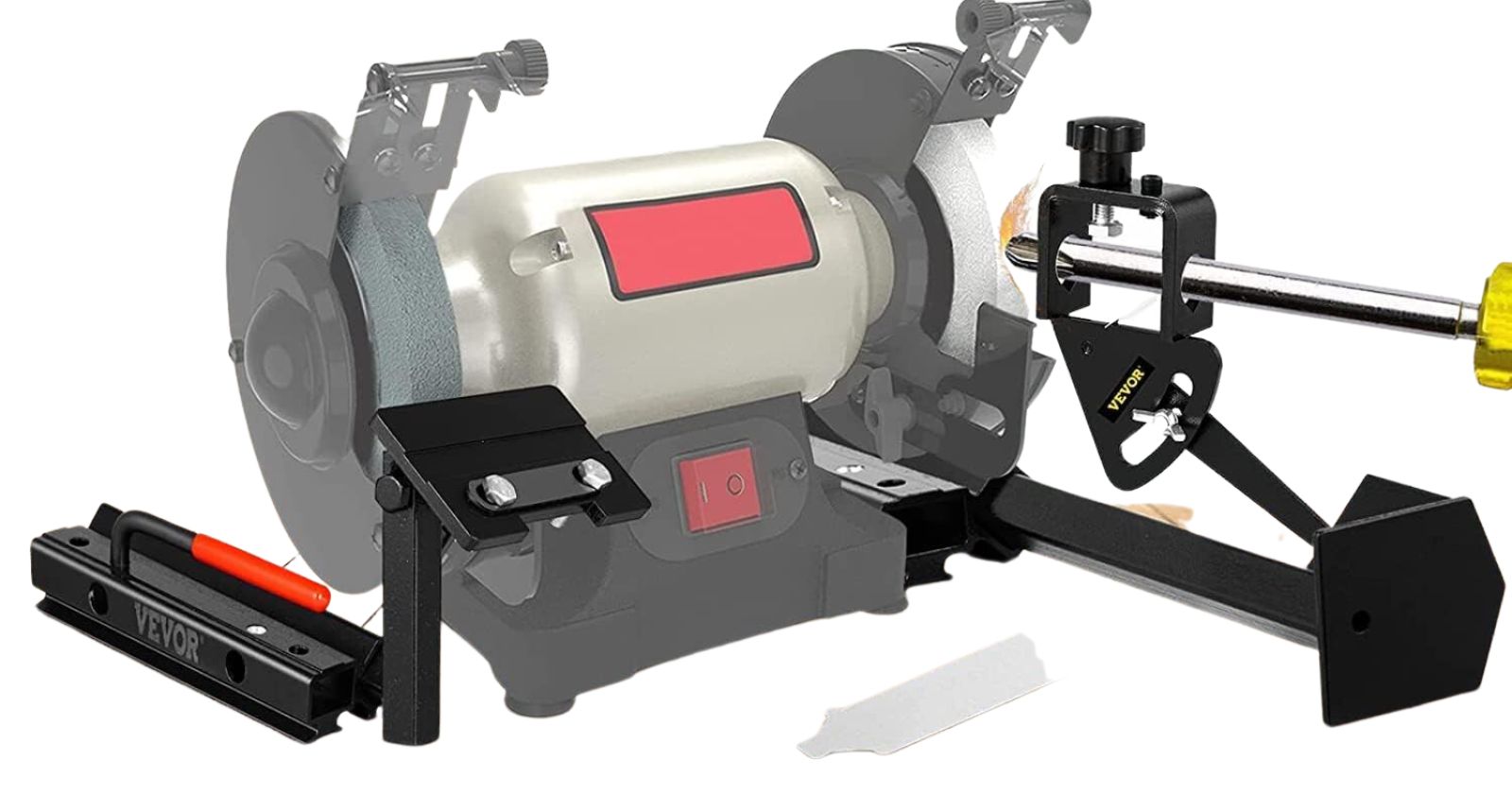

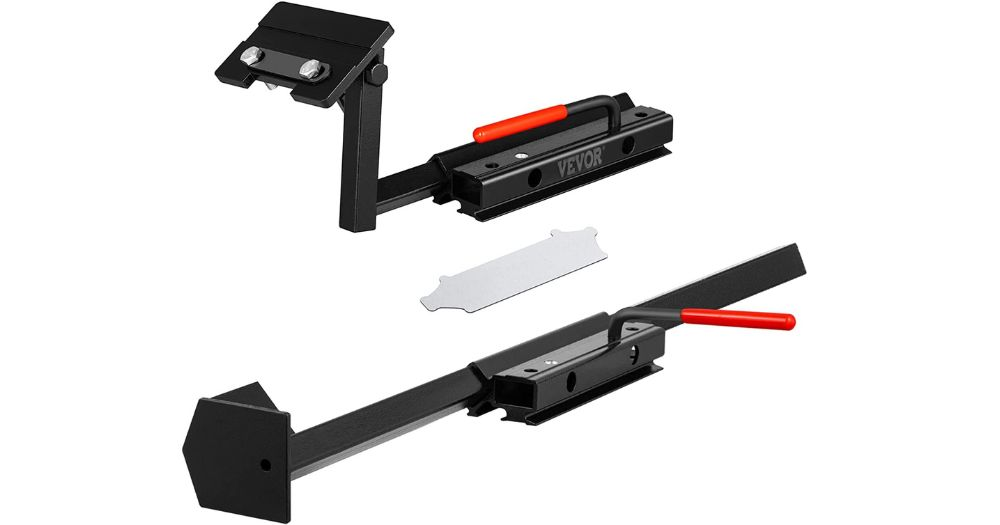

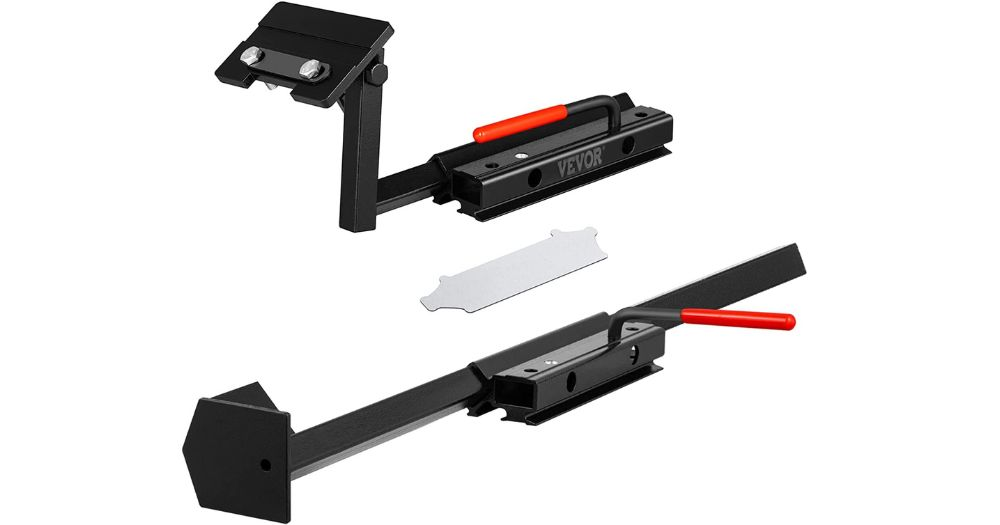

4. Wolverine Grinding System with VARI-GRIND Jig

The Wolverine System as a robust sharpening tool that seamlessly integrates with the Wolverine Grinding Jig. Made from durable iron, my system is built to withstand the test of time, featuring a scratch-resistant and powder-coated surface for added durability.

The vari-grind attachment I’ve included comes with a specialized platform that has an extra groove, ensuring it’s highly compatible with a variety of machines.

To make installation a breeze, I provide a hexagonal handle, along with a complete kit that includes a V-arm and a platform. I’ve also thrown in a 5-piece accessory set, featuring a fishboard ruler and knife grinding support bases. Whether you’re working with metal or wood, my system is the ideal replacement for conventional light-duty tool rests, optimized for use with standard bench-style grinders.

Pros

- Durability: Made of iron and featuring a scratch-resistant, powder-coated surface, the Wolverine System is built to last.

- Versatility: Suitable for most machinable rods and designed for both metal and wood blocks.

- Ease of Use: Comes with a hexagonal handle and a 5-piece set of accessories for easy installation and operation.

- Thoughtful Design: The added groove and wider fixing holes on the platform enhance compatibility and stability.

Cons

- Learning Curve: May be challenging for beginners to set up and use effectively.

- Size Limitations: The jig size may not be compatible with all types of rods or tools.

- Manual Installation: Some users may find the manual installation process to be cumbersome.

5. Pro Grind Multi-Grind Sharpening Jig

As a woodturning aficionado, the Multi-Grind Jig has revolutionized how I achieve precise grinds on my bowl and spindle gouges. The included setup blocks are a lifesaver, eliminating all guesswork and letting me zero in on the perfect grind.

What’s more, it’s compatible with any system that has a pocket v-arm attachment. This jig streamlines three crucial variables for me: the tool grind projection, the tool angle, and the pocket v-arm depth. Once everything is dialed in, the grinding process is smooth sailing, courtesy of the jig’s natural pivoting and rolling action.

Crafted from top-notch steel and featuring a silky brass knob and a non-marring PVC clamp pad, this jig is the epitome of accuracy and tool safety

Pros

- Pinpoint Accuracy: The setup blocks make it a cinch to quickly dial in the tool grind projection and angle.

- One Jig, Many Grinds: It’s a versatile beast, compatible with four basic types of grinds for both bowl and spindle gouges.

- User-Friendly: The jig simplifies three key variables, streamlining the setup process for me.

- Safety First: Its natural pivoting action is a built-in safety feature that keeps my fingers well away from the grinding wheel.

- Built to Last: The high-quality steel construction, complemented by a smooth brass knob and a non-marring PVC clamp pad, speaks volumes about its durability

Cons

- Initial Learning Curve: It’s straightforward, but the first-time setup can take a bit to get just right.

- System-Specific: It’s tailored for systems with a pocket v-arm attachment, which could be limiting.

- Manual Tweaks: While I don’t mind, some might prefer a more automated setup process.

The best grinder jig for your lathe largely depends on your specific needs and budget. Whether you prioritize durability, versatility, or safety, there’s a grinder jig out there that’s perfect for you. These top picks have served me well, and I hope they guide you in making an informed decision

Troubleshooting Common Issues with Grinder Jigs

Every craftsman, including myself, understands that even our most trusted tools can sometimes surprise us with unexpected challenges. And while grinder jigs have been a game-changer for many of my projects, they’re not without their quirks. Let me share with you some common issues I’ve faced and the solutions I’ve found:

1. Jig Slippage:

- Problem: My jig tends to move or shift during operation, messing up the sharpening consistency.

- Solution:

- Surface Preparation: Before I even think of mounting, I make sure the surface is spotless. Any tiny debris can cause the jig to slip.

- Tighten Everything: I’ve noticed that screws can get a bit loose over time. So, I make it a habit to check and tighten them regularly.

- Anti-Slip Pads: I’ve added some rubberized pads beneath my jig. It’s made a world of difference in stability.

2. Inconsistent Sharpening Angles:

- Problem: Sometimes, I find that my tool isn’t maintaining a steady angle during sharpening.

- Solution:

- Regular Calibration: I always calibrate my jig before sharpening to ensure the angle is spot on.

- Tool Placement: I double-check to make sure my tool sits just right in the jig.

- Debris Check: I’ve learned the hard way that even a speck of dust can throw off the angle. So, a quick clean is always in order.

3. Overheating of Tools:

- Problem: There have been times when my tool gets too hot during sharpening.

- Solution:

- Intermittent Sharpening: I’ve found that short, controlled bursts, rather than continuous grinding, keep the tool cooler.

- Water Dipping: I always keep a cup of water close by. Dipping the tool occasionally helps a lot.

- Gentle Pressure: I’ve learned that a softer touch can prevent excessive heat buildup.

4. Uneven Wear on the Grinding Surface:

- Problem: Sometimes, one part of the grinding surface wears down faster, leading to uneven sharpening.

- Solution:

- Regular Rotation: I make it a point to shift my tool’s position now and then. It ensures even wear.

- Wheel Dressing: If I’m using a grinding wheel, I dress it regularly to keep the surface even.

5. Difficulty in Adjusting the Jig:

- Problem: At times, the jig’s components feel stiff or don’t move as they should.

- Solution:

- Thorough Cleaning: I’ve found that a good clean can make a world of difference. Dust can be a real hindrance.

- Lubrication: A drop of machine oil or silicone lubricant keeps things moving smoothly.

- Damage Inspection: Every so often, I inspect my jig for any damage that might be causing issues.

6. Tool Doesn’t Fit Properly in the Jig:

- Problem: Sometimes, my tool doesn’t sit securely, or the jig doesn’t seem to fit it right.

- Solution:

- Correct Jig Selection: I’ve learned to ensure I’m using the right jig for each tool. Some of them need specialized jigs.

- Adjustable Components: The adjustable parts on modern jigs are a lifesaver. I always make sure they’re set up correctly for each tool.

Additional Tips for Smooth Operation:

- Routine Inspections: I always give my jig a quick check before using it. It’s saved me from many potential headaches.

- Stay Updated: I keep an eye out for any updates or guidelines from manufacturers. They often have valuable insights.

- Practice Makes Perfect: Like with all tools, the more I use my grinder jig, the better I get at it.

In my journey of woodworking, I’ve learned that the small details often make the biggest difference. And while challenges are part and parcel of the craft, they’re also opportunities to learn and grow. With a bit of patience and know-how, I’ve made my grinder jig an invaluable ally in my workshop. And I’m confident you can too!

FAQs: Top 5 Best Grinder Jig For Wood Lathe In 2024

As we wrap up our deep dive into grinder jigs for lathes, it’s natural to have a few lingering questions. Over the years, I’ve been asked countless queries about this essential tool. To help clarify any remaining uncertainties, I’ve compiled a list of the most frequently asked questions, along with their answers. These are designed to provide quick insights and are optimized for those searching on Google.

Why is material choice crucial for grinder jigs?

The material of a grinder jig determines its durability, stability, and longevity. Materials like steel or iron are preferred because they can withstand the pressures of regular sharpening sessions and won’t easily wear out. A robust grinder jig ensures consistent sharpening angles and results, making the material choice paramount for optimal performance.

How often should I maintain or clean my grinder jig?

Regular maintenance is key to the longevity and efficiency of your grinder jig. After each sharpening session, it’s advisable to brush off any residual debris. For moving parts, a drop of lubricant every few sessions ensures smooth operation. Additionally, a thorough cleaning and inspection every few months can help identify and address any potential issues before they become significant problems.

Can one grinder jig fit all my lathe tools?

While many modern grinder jigs are designed to be versatile and adjustable, accommodating a variety of tools, it’s essential to ensure the jig you choose fits the specific tools you intend to sharpen. Some specialized tools might require dedicated jigs. It’s always a good idea to check the manufacturer’s specifications and, if possible, test the jig with your tools before making a final decision.

Remember, the world of woodworking is vast and ever-evolving. While these FAQs address some common concerns, always stay curious and continue seeking knowledge. The journey of a craftsman is one of constant learning and growth.

As A Final Point Of The Top 5 Best Grinder Jig For Wood Lathe In 2024

As I wrap up my thoughts on this topic, I’m reminded of the countless hours I’ve spent in my workshop, surrounded by the hum of machinery and the scent of freshly cut wood. Over the years, I’ve come to understand that while talent and skill are essential, the tools we use can make or break our work. And in the realm of woodworking, the grinder jig for lathes stands out as a silent game-changer.

When I first started, I underestimated the importance of the grinder jig. It seemed like just another accessory. But as the projects grew more complex and the demand for precision heightened, the value of a reliable grinder jig became abundantly clear. It’s not just about sharpening a tool; it’s about ensuring that every piece of work reflects the best of our abilities.

Choosing the right grinder jig is akin to selecting the right paintbrush for an artist. It might seem insignificant to an outsider, but for the creator, it holds the power to transform a vision into reality. The right jig ensures that every tool is primed for perfection, every cut is precise, and every project is a testament to craftsmanship.

Over the years, I’ve learned that in woodworking, and in life, you often get what you pay for. Investing in a quality grinder jig might seem like a luxury at first, but when you weigh it against the benefits – the time saved, the precision achieved, the longevity of your tools – it quickly becomes evident that it’s a necessity. It’s an investment that pays dividends in the form of superior work quality and personal satisfaction.

To all the craftsmen and enthusiasts reading this, I urge you to view your tools not just as instruments but as extensions of yourself. They represent your commitment to your craft, your dedication to excellence, and your passion for creating. And in this toolkit, a grinder jig, though unassuming, is a cornerstone.

So, as you continue on your woodworking journey, remember the pivotal role of the grinder jig. Embrace it, invest in it, and watch as it elevates your work to new heights. Because at the end of the day, our work is not just about creating objects; it’s about leaving a legacy of excellence.

To precision, passion, and the beautiful dance between a craftsman and their tools. Cheers to the endless journey of creation!

More Grinder Jig For Wood Lathe Post:

Here Are Some Additional guides and content about Grinder Jig For Wood Lathe

- How To Use A Grinding Jig For Lathe Tool Safely In 2023

- The 5 Best Wood Lathe Tool Sharpening System Of 2023

- Top 5 Best Slow Speed Bench Grinders for Sharpening: A Beginner’s Guide for 2023

.