When Not To Use An Impact Driver: A Comprehensive Guide

As a contractor and tool enthusiast, I have learned firsthand that impact drivers are incredibly useful for a wide range of applications. I’ve experienced how they can make quick work of any project, and their power and torque are unmatched. However, I’ve also come to understand that there are times when an impact driver should not be used. In this comprehensive guide, I will discuss when I recommend avoiding the use of an impact driver and share some helpful tips to keep in mind.

What is an Impact Driver?

Before we dive into the topic of when not to use an impact driver, let’s first define what an impact driver is. An impact driver is a power tool that is similar in appearance to a drill. It uses concussive force to drive screws and other fasteners into a surface. The concussive force is generated by an internal hammer mechanism that delivers rapid rotational blows. Impact drivers are highly efficient and can make quick work of any project.

When Not to Use an Impact Driver

While impact drivers are incredibly powerful, there are times when they should not be used. Here are some situations where an impact driver should not be used:

Soft Materials

Impact drivers generate a lot of torque and power, which can be problematic when used on soft materials. Soft materials, such as drywall, can be easily damaged when using an impact driver. The concussive force generated by the tool can cause the material to crack or break, leaving you with a damaged surface.

Delicate Jobs

When you are working on a delicate job that requires finesse and precision, an impact driver should not be used. Impact drivers are designed for speed and power, not precision. If you are working on a project that requires you to be careful and precise, such as installing trim or molding, you should use a traditional drill instead.

Tight Spaces

Impact drivers are often larger and bulkier than traditional drills. This can make it difficult to use them in tight spaces, such as between studs or in a cramped corner. When working in tight spaces, a smaller and more maneuverable tool, such as a right-angle drill, may be a better option.

Watch This Video And Learn When Not To Use An Impact Driver

Perhaps it’s time to consider a brand new impact driver. Check out the Best Impact Driver Drill Under $100.

Polished Surfacest

Impact drivers can also cause damage to polished surfaces, such as hardwood floors or delicate tiles. The concussive force generated by the tool can cause scratches or other types of damage to the surface. If you need to work on a polished surface, you should use a tool that is specifically designed for the task, such as a manual screwdriver.

Uses for an Impact Driver

Tips for Using an Impact Driver

While there are times when an impact driver should not be used, they are still incredibly useful tools. Here are some tips to keep in mind when using an impact driver:

Use the Right Bit

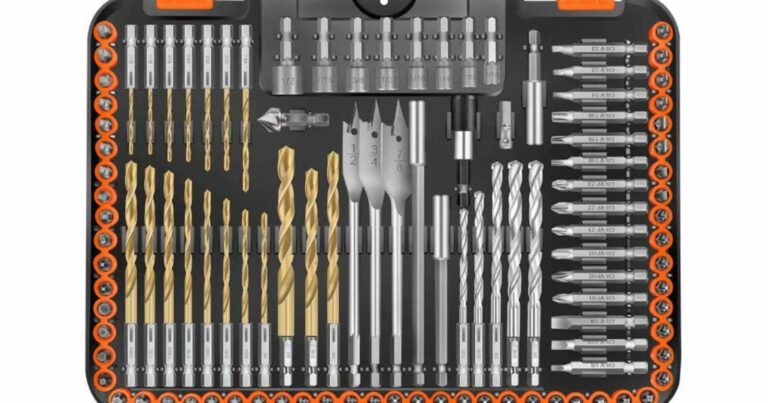

The bit that you use with your impact driver can make a big difference in the success of your project. Using the wrong bit can cause damage to the fastener or the surface that you are working on. Make sure that you are using the correct bit for the job and that it is properly secured in the chuck.

Use the Right Power Setting

Impact drivers often come with multiple power settings, which can be adjusted depending on the task at hand. Using too much power can cause damage to the material, while using too little power can result in a poorly secured fastener. Make sure that you are using the correct power setting for the job.

Wear Safety Gear

As with any power tool, it is important to wear the appropriate safety gear when using an impact driver. This includes safety glasses, gloves, and ear protection. The high torque and power generated by the tool can cause debris to fly, which can be dangerous if it hits your eyes or skin. Ear protection is also important, as the tool can be quite loud and can cause damage to your hearing over time.

Check the Battery

Before you begin using your impact driver, it is important to check the battery. Make sure that it is fully charged and that it will last for the duration of your project. Running out of battery in the middle of a project can be frustrating and time-consuming.

Perhaps it’s time to consider acquiring a new battery. Check out the Best Impact Driver Replacement Battery.

Use the Right Attachments

In addition to using the right bit, it is also important to use the right attachments with your impact driver. This can include things like sockets and adapters. Using the wrong attachment can cause damage to the tool or the fastener.

Alternatives to Impact Drivers

While impact drivers are incredibly versatile and powerful tools, they may not always be the best choice for every job. Certain tasks require a more delicate touch or a different type of tool altogether. In this section, we’ll explore some alternatives to impact drivers that can be used effectively in various situations.

Soft Materials

When working with soft materials like drywall or thin wood, the high torque and power of an impact driver can be overkill and may even cause damage. In these instances, a standard drill or screwdriver is often a better choice. These tools provide more control and are less likely to damage the material.

Delicate Jobs

For tasks that require precision and finesse, such as installing trim or molding, a cordless drill or manual screwdriver is often the best tool for the job. These tools allow for more control over speed and depth, ensuring a clean and precise finish.

Tight Spaces

Impact drivers can be bulky and may not fit into tight spaces. When working in cramped corners or between studs, a right-angle drill is an excellent alternative. Its compact design allows it to fit into tight spaces while still providing the power needed to get the job done.

Drilling Holes

While impact drivers can technically drill holes, they are not designed for this purpose and can be difficult to control. A standard drill or hammer drill is a better choice for drilling holes, especially in hard materials like concrete or masonry.

High Precision Tasks

For tasks that require a high level of precision, such as assembling furniture or electronics, a cordless screwdriver is a great choice. These tools often have adjustable torque settings, allowing you to control the amount of force applied and prevent over-tightening.

Heavy-Duty Tasks

For heavy-duty tasks that require a lot of power, such as driving long screws into hard materials, a hammer drill or impact wrench might be a better choice. These tools deliver a high amount of torque and are designed to handle tough jobs.

Remember, the key to successful DIY projects is using the right tool for the job. While impact drivers are a great addition to any toolbox, they are not always the best tool for every task. By understanding the strengths and limitations of each tool, you can choose the best one for your specific project and ensure a successful outcome.

Impact Driver vs. Other Tools: A Personal Comparative Analysis

When I’m working with power tools, I find it crucial to understand the differences between various types to ensure I’m using the right tool for the job. In this section, I’ll share my personal experiences comparing impact drivers with other similar tools, such as standard drills and hammer drills, highlighting their differences in functionality, power, usage, and cost.

Impact Driver vs. Standard Drill

Functionality: I’ve found that standard drills are versatile tools designed to create holes and drive screws. They offer a high level of control, making them suitable for precision tasks. On the other hand, impact drivers are designed to drive screws and other fasteners. They use a combination of rotational force and concussive impact, making them ideal for driving long screws or bolts into hard materials.

Power: In my experience, impact drivers typically deliver more torque than standard drills. This makes them more efficient at driving screws into dense materials without stripping the screw head or damaging the material.

Usage: I often use standard drills for a wide range of tasks, from drilling holes to driving screws, making them a versatile addition to my toolbox. Impact drivers, however, are more specialized tools, best used for tasks that require high torque, such as constructing decks or installing heavy-duty fasteners.

Cost: I’ve noticed that standard drills are usually less expensive than impact drivers. However, the cost can vary depending on the brand, power, and additional features of the tool.

Impact Driver vs. Hammer Drill

Functionality: Hammer drills are designed to drill into hard materials like concrete or masonry. They use a hammering action to deliver a rapid succession of blows that pulverize the material, making it easier to drill. Impact drivers, on the other hand, are designed to drive screws and bolts, using both rotational and concussive force.

Power: Both tools deliver high power, but in different ways. Hammer drills provide high impact energy, ideal for drilling into hard materials. Impact drivers deliver high torque, making them excellent for driving screws and bolts.

Usage: I typically use hammer drills for heavy-duty tasks, such as drilling into concrete or masonry. Impact drivers are more suited for tasks that require high torque, such as driving long screws or heavy-duty fasteners.

Cost: Hammer drills are generally more expensive than impact drivers due to their specialized functionality. However, prices can vary depending on the brand, power, and additional features.

In conclusion, while impact drivers, standard drills, and hammer drills may look similar, they each have unique functionalities that make them suited to different tasks. Understanding these differences has helped me choose the right tool for my projects and ensure successful outcomes. I always consider the nature of the task, the materials I’m working with, and my budget when choosing a power tool.

FAQs About When Not To Use An Impact Driver

If you’re new to using impact drivers, you might have some questions. Here are a few frequently asked questions and their answers:

Can an impact driver be used as a drill?

While impact drivers may look similar to drills, they are not designed to be used in the same way. Impact drivers are designed to drive screws and other fasteners into surfaces, while drills are designed to make holes. While you can technically use an impact driver to drill a hole, it’s not recommended as it can be difficult to control and can damage the bit.

Can an impact driver be used to remove screws?

Yes, an impact driver can be used to remove screws. In fact, it can be easier to remove screws with an impact driver than with a traditional screwdriver. The concussive force generated by the tool can help to break loose stubborn screws that might be difficult to remove otherwise.

What type of maintenance does an impact driver require?

Like any power tool, an impact driver requires regular maintenance to keep it in good working order. This includes keeping it clean and lubricated, checking the battery or power source, and inspecting the tool for any signs of damage or wear. It’s also important to use the tool in the proper way and to follow the manufacturer’s recommendations for maintenance and repair.

Final Thoughts on Proper Usage of an Impact Driver

Impact drivers are incredibly powerful and efficient tools that can make quick work of any project. However, they are not suitable for every situation. It is important to know when not to use an impact driver to avoid damaging materials or creating a dangerous situation. By keeping the tips and guidelines in mind, you can use your impact driver safely and effectively. Remember to wear the appropriate safety gear, use the right bit and attachments, and use the correct power setting for the job. With these tips in mind, you can make the most of your impact driver and complete your projects with ease.

More Troubleshooting Guides:

Here Are A Few More Guides To Help You Along Your Building Journey.