Best Impact Driver Clamps

Impact driver clamps are indispensable tools that enable me to securely fasten materials in place while using my impact driver. Whether you’re a DIY enthusiast like me or a professional contractor, having a reliable and sturdy clamp can significantly enhance your projects. However, with the sheer number of clamps available on the market, choosing the best one for your needs can be quite a challenge. That’s exactly why I’ve researched and tested some of the most sought-after impact driver clamps on the market, compiling a list of the top options at hand. In this post, I’ll talk about the key factors to consider when choosing an impact driver clamp and review my top picks to help us make a well-informed decision.

Why You Should Get An Impact Driver Drill Clamps

Improved Precision

Enhanced Safety

Impact drivers generate a lot of torque, which can cause your workpiece to move or spin unexpectedly if it’s not properly secured. This can not only damage your project, but it can also be dangerous for you as the operator. Clamps help prevent this by keeping your workpiece securely in place, reducing the risk of accidents.

Increased Efficiency

With clamps, you can work faster and more efficiently, as you don’t have to stop and readjust your workpiece every time you need to make a cut or drive a screw. This saves you time and energy, allowing you to complete your projects more quickly and easily. Additionally, many clamps are designed to be easily adjustable and quick to set up, making them an excellent addition to any workshop or job site.

What to Look For When Buying a impact driver clamps

Grip strength

Look for clamps that have a strong grip and can hold materials firmly in place. Clamps with soft, rubberized pads or grips can be especially effective at providing a secure hold without damaging the workpiece.

Perhaps its time to consider a new Drill . Take a look at the Best Drill Under $100.

Compatibility

Make sure the clamp you choose is compatible with your impact driver drill. Some clamps are designed specifically for certain types of impact drivers, so be sure to check the product specifications before making a purchase.

Versatility

Consider the types of materials you’ll be working with and choose a clamp that can accommodate a variety of sizes and shapes. Look for clamps that have adjustable jaws or can be easily repositioned to hold materials at different angles or orientations. This can increase the versatility and usefulness of the clamp in a variety of projects.

Watch This Video And Learn About The Best Impact Driver Clamps.

Troubleshooting Guide for Impact Driver Clamps

Even with the best tools, you may occasionally encounter issues. Here are some common problems you might face with your impact driver clamps and how to solve them:

Clamp Slipping:

If your clamp is slipping off the workpiece, it could be due to a lack of grip. Check the pads of the clamp for wear and tear. If they’re worn out, consider replacing them or the entire clamp. Also, ensure the workpiece and clamp are clean and free of any lubricant or debris that could cause slippage.

Difficulty in Adjusting Clamp:

If you’re having trouble adjusting the clamp, it could be due to rust or debris in the threads or moving parts. Clean the clamp thoroughly and apply a lubricant to the threads and moving parts.

Clamp Not Holding Tight:

If the clamp isn’t holding as tightly as it should, it could be due to wear in the mechanism or a weak spring. Check the condition of the spring and the tightening mechanism. If they’re worn out, it might be time for a replacement.

Rusting:

If you notice rust on your clamp, clean it off using a wire brush and then apply a rust remover. To prevent future rust, keep the clamp dry and consider applying a thin layer of oil or WD-40 to the metal parts.

Broken or Damaged Parts:

If any part of the clamp is broken or damaged, it’s usually best to replace the entire clamp. Using a damaged clamp can be dangerous and could result in poor quality work.

Remember, if you’re ever unsure about a repair or the safety of a clamp, it’s best to consult with a professional or replace the tool. Safety should always be your top priority when working with any tool.

Maintenance Tips for Impact Driver Clamps

Proper maintenance of your impact driver clamps can significantly extend their lifespan and ensure they continue to perform at their best. Here are some tips to help you take care of your clamps:

Regular Cleaning:

After each use, clean your clamps to remove any dust, debris, or residue. You can use a dry cloth for this purpose. If there’s stubborn grime, a mild detergent and warm water can be used, but ensure the clamp is thoroughly dried afterwards to prevent rusting.

Rust Prevention:

To prevent rust, consider applying a thin layer of oil or WD-40 to the metal parts of your clamps. This is particularly important if you’re storing your clamps in a humid environment.

Regular Inspection:

Regularly inspect your clamps for any signs of wear and tear. Check the grip, the spring, and the frame for any damage. If you notice any issues, it might be time to replace your clamp to ensure your safety and the quality of your work.

Proper Storage:

Store your clamps in a cool, dry place to prevent rust and damage. Avoid leaving them in places with extreme temperatures or high humidity. If possible, hang your clamps rather than piling them up. This can prevent unnecessary pressure and potential damage.

Avoid Overloading:

Each clamp is designed to handle a certain amount of pressure. Avoid using your clamps for heavier loads than they’re designed for, as this can cause them to warp or break.

Lubrication:

Occasionally, apply a small amount of lubricant to the moving parts of your clamps. This can help them operate smoothly and prevent wear and tear.

Remember, taking care of your tools is an investment in their longevity and in the quality of your work. With these maintenance tips, your impact driver clamps should serve you well for many projects to come.

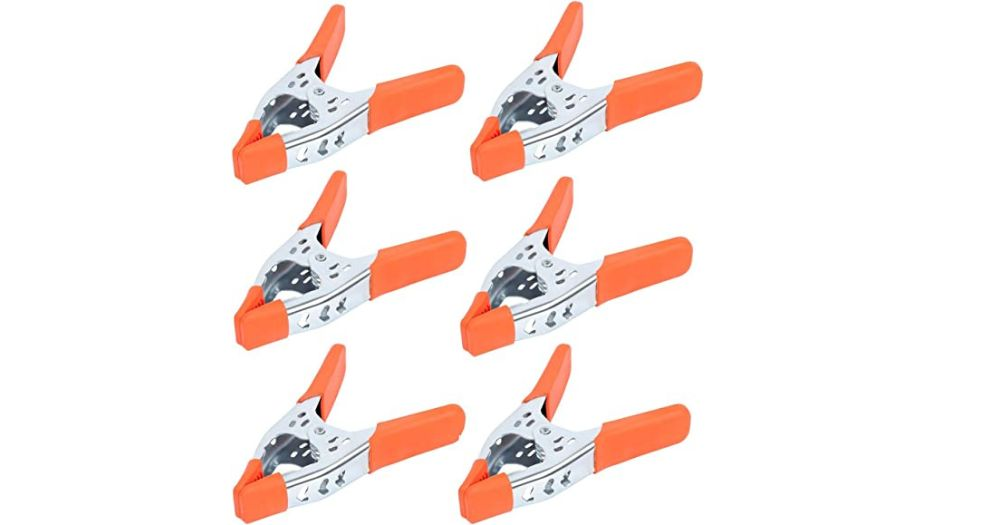

1. HORUSDY

HORUSDY 6-Piece 6″ inch Spring Clamp, the ultimate solution for all your clamping needs. Designed with ease of use in mind, these clamps are incredibly user-friendly, allowing you to secure objects effortlessly. Crafted with sturdy materials, they provide unparalleled sturdiness, ensuring a reliable grip that won’t let you down. With exceptional value for money, this 6-piece set offers a versatile and cost-effective solution for various projects. Moreover, the HORUSDY Spring Clamps are built to last, boasting outstanding durability that can withstand the test of time. Whether you’re a DIY enthusiast or a professional, these clamps are the perfect addition to your toolbox, delivering convenience, strength, value, and longevity in one exceptional product.

Pros :

- Heavy-duty

- Non-slip plastic cover

- Suitable for wood

Cons:

- Tips fell off

2. TOLESA

RIDA Impact Driver Kit, a product that embodies versatility, light weight, sturdiness, and exceptional value for money. This kit is designed to cater to a wide range of tasks, allowing you to effortlessly tackle various projects with ease. Its lightweight construction ensures comfortable handling and reduces fatigue during extended use. Crafted with durability in mind, the RIDA Impact Driver Kit offers a robust and reliable performance, capable of withstanding demanding applications. With its unbeatable value for money, this kit provides an exceptional combination of quality, functionality, and affordability. Experience the ultimate convenience and efficiency with the RIDA Impact Driver Kit.

Pros:

- Powerful Clamping Force

- Lightweight

- Heavy duty

Cons

- Tips break easily

3. Jorgensen

Jorgensen 6″ One Hand Clamp/Spreader — a highly versatile, user-friendly, and cost-effective tool that ensures reliable performance in any project. With its intuitive design, this clamp effortlessly transitions between clamping and spreading applications, providing maximum convenience. Crafted with robust materials, it offers exceptional sturdiness, guaranteeing a secure grip and lasting durability. Whether you’re a professional craftsman or a DIY enthusiast, the Jorgensen 6″ One Hand Clamp/Spreader is the perfect choice for achieving excellent results while staying within budget.

Pros :

- Reinforced nylon jaw

- Quick-release lever

- Removable and replaceable pads

FAQs: Best Impact Driver Clamps

If you’re considering purchasing an impact driver clamp, you may have a few questions about how they work and what to look for. To help you make an informed decision, I’ve compiled a list of frequently asked questions (FAQs) about impact driver drill clamps. From maximum jaw openings to compatibility with your drill, these FAQs cover some of the most important things you need to know before purchasing an impact driver clamp.

What is the maximum jaw opening of an impact driver clamp?

The maximum jaw opening of an impact driver clamp can vary depending on the specific product. Some clamps have a maximum jaw opening of 2 inches, while others can open up to 6 inches or more. Be sure to check the product specifications to determine the maximum jaw opening of the clamp you’re considering.

Can I use a regular clamp with an impact driver drill?

While you may be able to use a regular clamp with an impact driver drill, it’s not recommended. Regular clamps are not designed to withstand the high torque and rapid vibrations generated by impact drivers, which can cause them to slip or even break. It’s important to use a clamp specifically designed for use with an impact driver to ensure a safe and secure grip on your workpiece.

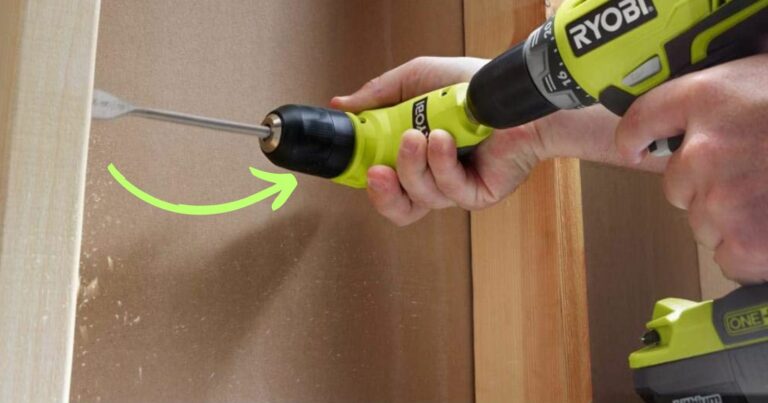

How do I properly attach an impact driver clamp to my drill?

Attaching an impact driver clamp to your drill is usually a straightforward process. Simply insert the shank of the clamp into the chuck of your impact driver and tighten it securely. Be sure to follow the manufacturer’s instructions and use the appropriate chuck size for your clamp. Once the clamp is securely attached, adjust the jaws to fit the material you’re working with and tighten them down to provide a secure hold.

Suggested Reading: When Not To Use An Impact Driver: A Comprehensive Guide

Wrapping Up Things With The Best Impact Driver Clamps

In choosing the best impact driver clamp depends on various factors such as the type of project, material, and budget. It is essential to consider the clamp’s gripping power, size, and compatibility with the impact driver before making a purchase. Additionally, it is advisable to read reviews and seek recommendations from professionals to ensure that you choose a high-quality and durable impact driver clamp that meets your needs. With the right impact driver clamp, you can achieve accurate and efficient results while working on your DIY or professional projects.