The Best Impact Driver Workhorse

When it comes to handling demanding tasks, possessing the right impact driver workhorse makes a world of difference. As a member of the DIYer and professional community, I consider the impact driver to be one of the most vital tools in my toolkit. However, with the myriad of models and brands up for grabs in the market, deciding on the right one can be quite a task. That’s precisely why I’ve compiled this list of the best impact driver workhorses. Whether you’re driving screws into tough materials or drilling through dense wood, these impact drivers are guaranteed to complete the job promptly and efficiently. So, let’s take a look together at some of the market’s top performers today.

| # | Image Preview | Product | Rating |

|---|---|---|---|

| 1 |  | ToughBuilt | 4.5/5 |

| 2 |  | WORKESS | 4/5 |

| 3 |  | WORKPRO | 3/5 |

Why You Should Get Impact Driver Workhorses

More Power:

A workhorse impact driver usually has a more powerful motor than standard models, allowing it to deliver higher torque and speed. This makes it easier to drive screws into tough materials like hardwood or metal, or to drill through thick materials like concrete or masonry.

Increased Durability:

Workhorse impact drivers are designed with durability in mind. They are built with high-quality materials, such as heavy-duty steel or aluminum, which can withstand the wear and tear of regular use. Additionally, many workhorse models come with features like protective rubber bumpers or reinforced housing to help protect against accidental drops or impacts.

Versatility:

Workhorse impact drivers often come with a range of features and attachments that make them more versatile than standard models. For example, some work horse models may include multiple speed settings or adjustable torque, allowing you to fine-tune the tool to suit a variety of tasks. Additionally, many workhorse impact drivers are compatible with a range of drill bits and screwdriver bits, making them ideal for a variety of applications.

What to Look For When Buying work horses

Torque and Speed:

Workhorse impact drivers are designed to deliver more torque and speed than standard models, making them ideal for tougher jobs. When selecting an impact driver work horse, consider the maximum torque and speed ratings, as well as any variable speed settings or other features that allow you to adjust the tool’s power output to suit different tasks.

Build Quality:

The build quality of the impact driver workhorse can impact its durability and longevity. Look for models with sturdy construction, such as heavy-duty metal housing and reinforced internal components. Additionally, consider features like rubberized grips or shock-absorbing bumpers that can help protect the tool from damage in case of drops or impacts.

Battery Life:

Since workhorse impact drivers are designed for heavy use, it’s important to select a model with a battery that can deliver sufficient runtime. Look for models with high-capacity batteries or ones that are compatible with extended-life batteries. Additionally, consider features like battery level indicators or quick charging times that can help you stay productive on the job site.

Maintenance Tips for Your Impact Driver Workhorse

Proper maintenance of your impact driver workhorse is crucial to ensure its longevity and optimal performance. Here are some tips to help you keep your tool in the best possible condition:

1. Regular Cleaning:

After each use, make sure to clean your impact driver. Use a dry cloth to wipe away any dust or debris from the tool’s surface. For stubborn dirt, you can use a soft brush. Avoid using harsh chemicals or water, as these can damage the tool’s components.

2. Proper Storage:

Always store your impact driver in a cool, dry place to prevent rust and corrosion. If your tool came with a case, make sure to use it. The case will not only protect the tool from dust and moisture but also from accidental drops or impacts.

3. Regular Inspection:

Before each use, inspect your impact driver for any signs of damage or wear. Check the cord, switches, and other components. If you notice anything unusual, such as a frayed cord or a loose part, make sure to repair or replace it before using the tool.

4. Lubrication:

Some parts of your impact driver may need regular lubrication to function smoothly. Refer to your tool’s manual to see if this is necessary and what type of lubricant you should use.

5. Battery Care:

If your impact driver is cordless, proper battery care is essential. Always remove the battery from the tool when it’s not in use. Avoid overcharging the battery, and try to keep it at room temperature. Extreme temperatures can damage the battery and shorten its lifespan.

6. Use the Right Bits:

Using the wrong bits can not only damage the bit itself but also the tool. Always make sure to use bits that are designed for your specific impact driver and the task at hand.

Remember, regular maintenance can significantly extend the life of your impact driver workhorse and ensure it always performs at its best. Always refer to your tool’s user manual for specific maintenance instructions and safety guidelines.

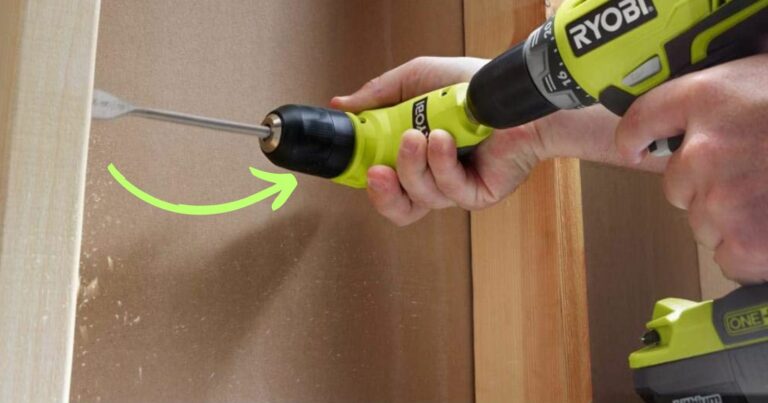

Watch This Video and Learn About The Best Impact Driver Workhorse

Perhaps its time to consider a new pair of impact driver gloves . Take a look at the Best Impact Driver Gloves

Safety Tips for Using Your Impact Driver Workhorse

While impact drivers are incredibly useful tools, they can also pose safety risks if not used correctly. Here are some safety tips to keep in mind when using your impact driver workhorse:

1. Wear Protective Gear:

Always wear safety glasses to protect your eyes from flying debris. If you’re working in a noisy environment, consider using ear protection as well. Gloves can protect your hands, but make sure they don’t interfere with your ability to grip and operate the tool safely.

2. Secure Your Workpiece:

Ensure the material you’re working on is securely fastened or clamped down. This prevents it from moving unexpectedly, which could cause injury or damage the tool.

3. Use the Right Bits:

Always use the correct bit for the task at hand. Using the wrong bit can cause it to break or the tool to malfunction, both of which can be dangerous.

4. Keep Your Work Area Clean:

A clean work area is a safe work area. Regularly remove debris and keep your tools organized to preventuig accidents.

5. Handle the Tool Correctly:

Always hold the impact driver with both hands for maximum control. Keep your hands away from the rotating bit.

6. Don’t Force the Tool:

Never force the impact driver into a workpiece. Let the tool do the work. Applying too much pressure can cause the bit to break or the tool to slip.

7. Maintain Your Tool:

Regularly inspect your impact driver for signs of wear or damage. A well-maintained tool is not only more efficient but also safer to use.

8. Be Aware of Your Surroundings:

Be mindful of where the power cord is (for corded models) to avoid tripping or cutting it. If you’re using a cordless model, be aware of where the battery is and ensure it’s securely in place.

Remember, safety should always be your top priority when using power tools. Always follow the manufacturer’s instructions and don’t hesitate to ask for professional advice if you’re unsure about something.

1. ToughBuilt

ToughBuilt Folding Sawhorse/Jobsite Table, the ultimate combination of sturdiness, versatility, maneuverability, and unbeatable value for money. This robust and durable tool is designed to handle any task with ease, providing a solid and reliable support system. Crafted with high-quality materials, it ensures long-lasting performance and can withstand heavy-duty use. Additionally, its lightweight design allows for effortless transportation and hassle-free maneuverability on the job site. Whether you need a sturdy sawhorse or a reliable jobsite table, this ToughBuilt product delivers exceptional strength and functionality. Invest in this folding sawhorse/jobsite table to experience unmatched durability, adaptability, and incredible value for your money.

Pros:

- Easy to use

- Easy to fold

- Light weight

Cons:

Collasing issues

2. WORKESS

WORKESS Saw Horses 2 Pack, the ultimate solution for woodworking enthusiasts. These heavy-duty folding saw horses combine convenience, sturdiness, and stability to enhance your working experience. With their easy-to-fold design, setting up and packing away has never been easier. Each saw horse can support an impressive 2200 lbs load capacity, thanks to the robust 2×4 support legs. The fast open legs and easy grip handle ensure quick and effortless maneuverability. Whether you’re a professional carpenter or a DIY enthusiast, WORKESS Saw Horses are the perfect addition to your workshop, providing reliable support and unmatched durability.

Pros:

- Heavy duty

- Adjustable height legs

- Easy carry handles

Cons :

Legs are a bit thin

3. WORKPRO

WORKPRO Portable Folding Sawhorse, a reliable solution for all your heavy-duty projects. Designed with stability in mind, these sawhorses provide a solid base to support up to 1000 lbs. of weight. With pivoting feet and adjustable height legs, you can easily set them up on any surface, ensuring a sturdy and level working area. When it’s time to pack up, these sawhorses fold effortlessly, making transportation and storage a breeze. Equipped with an easy carry handle, you can conveniently take them wherever your work takes you. Experience the perfect combination of stability, easy folding, and sturdiness with the WORKPRO Portable Folding Sawhorse.

Pros:

- Heavy duty

- Fast open legs

- Easy grip handles

Cons :

Unbelievably heavy

Troubleshooting Guide: Experiences and Solutions

Over the years, I’ve encountered a few hiccups while using my impact driver workhorse. I believe it’s important to share these experiences, along with the solutions I’ve found, to help you navigate any similar issues you might face. So, let’s dive into some common problems and their respective solutions that I’ve discovered while using my impact driver workhorse.

One issue that I’ve come across is the tool not starting. This can be quite frustrating, especially when you’re ready to start a project. In my experience, this is often due to a problem with the battery or the power connection. I usually start by checking the battery – is it properly inserted? Is it fully charged? If the battery seems fine, I then check the power switch and the cord for any visible damage. If all these are in order, it might be time to consult a professional or contact the manufacturer.

Another common problem I’ve faced is the battery not charging. This can be due to a faulty charger, a damaged battery, or even a power outlet issue. I start by trying a different power outlet or testing the charger with a different battery if one is available. If the battery still doesn’t charge, it might be time to replace it or the charger.

Lastly, there have been instances where my impact driver workhorse wasn’t delivering the expected power. This can be due to a variety of reasons, such as a low battery, a worn-out bit, or internal damage to the tool. I usually start by ensuring the battery is fully charged. If that’s not the issue, I check the bit – is it the right one for the job? Is it worn out? If the bit is fine, then it might be an internal issue, and it’s best to consult a professional or the manufacturer.

Remember, these are just a few common issues that you might encounter. There could be other problems specific to your model or brand. Always refer to your tool’s user manual for specific troubleshooting instructions and safety guidelines. And don’t hesitate to reach out to a professional or the manufacturer if you’re unsure about something. After all, it’s better to be safe than sorry when dealing with power tools.

FAQs: The Best Impact Driver Workhorse

Impact driver work horses are powerful tools that can tackle even the toughest jobs. As with any tool, there may be questions about how to choose the right model, what features to look for, and how to use the tool safely and effectively. In this section, I will provide answers to some common FAQs about impact driver work horses. Whether you’re a professional contractor or a DIY enthusiast, these FAQs can help you select the right tool for your needs and get the most out of your impact driver work horse.

What is an impact driver work horse?

An impact driver work horse is a high-powered impact driver designed to handle tougher jobs. These tools typically feature powerful motors, high maximum torque ratings, and durable construction materials, making them ideal for professionals and serious DIYers who need to tackle demanding tasks.

What is the difference between a regular impact driver and an impact driver work horse?

The main difference between a regular impact driver and an impact driver work horse is the power and performance. Workhorse impact drivers typically have more powerful motors, higher maximum torque ratings, and faster speeds than standard models. Additionally, workhorse models often feature sturdier construction materials and additional features to enhance durability and performance.

What are some of the advantages of using an impact driver work horse?

Using an impact driver work horse can provide several advantages over a standard impact driver. These tools are designed to handle tougher jobs and can deliver higher torque and speed, making them more efficient at driving screws and drilling through tough materials. Additionally, workhorse models are typically built to withstand more wear and tear, meaning they can last longer and require less maintenance over time. Finally, workhorse impact drivers often come with additional features and attachments that make them more versatile and adaptable to different tasks.

Suggested Reading: Can You Drill A Hole In Glass Without Breaking It?

Wrapping Up The Best Impact Driver Workhorse

When looking for the best impact driver workhorse, it’s important to consider a few key factors. The ideal impact driver workhorse should be powerful, efficient, durable, and versatile. It should also be easy to use and comfortable to hold, even during extended periods of use. After careful research and analysis, I have concluded that the best impact driver workhorse should have a brushless motor, multiple speed settings, and a compact design that is easy to maneuver. It should also have a long-lasting battery and a sturdy construction that can withstand heavy use. Ultimately, the best impact driver workhorse will depend on your specific needs and preferences. By considering the key factors mentioned above, you can choose the impact driver workhorse that is right for you.

Join our community by leaving a comment below. Share your experiences, tips, or questions about using a impact driver workhorse. Happy Crafting!!!